Pressure-fed Cyclone

High sorting efficiency: Clean coal, medium coal and gangue are sorted out in one go with a single low-density heavy medium, and the process system is simple and reliable.

Large processing capacity: High upper limit of feeding and strong gangue discharge capacity, suitable for materials with large variations in gangue content.

Strong wear resistance: Made of high-performance wear-resistant materials, it has a long service life

Adjustable separation density: The separation density of the first and second stages can be adjusted online steplessly to meet the requirements of different coal qualities.

Energy conservation and consumption reduction: Pressureless feeding eliminates the need for pumping, reducing power consumption and equipment wear

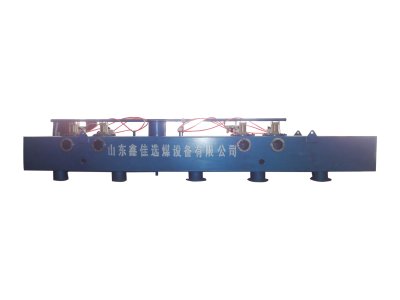

The pressure feeding cyclone separator adopts a vertical cylindrical structure, and its interior is divided along the axial direction into the liquid collection zone, cyclone separation zone, purification chamber zone, etc. The interior is equipped with cyclone sub-components, which are evenly arranged in the circumferential direction and fixed by upper and lower tube plates. The equipment is supported by a skirt seat, and the end caps adopt high-pressure resistant elliptical end caps.

Structural feature three:

Product sorting: It has three discharge ports and can simultaneously produce clean coal, medium coal and gangue.

Two-stage design: The first stage is cylindrical and the second stage is cylindrical conical, which improves the sorting accuracy

Medium recycling: Heavy medium suspensions can be recycled, reducing operating costs.

Regular maintenance and cleaning: Clear the internal sediment and debris to keep the equipment clean

Check for wear: Regularly replace worn parts and inspect the sealing performance.

Lubrication and maintenance: Pay attention to the lubrication of the equipment and change the lubricating oil regularly.

Due to its reasonable structure, high sorting efficiency and low operating cost, this equipment has become one of the preferred main selection devices in modern coal preparation plants.

| Specification | First-Stage Cylinder Diameter (mm) | Second-Stage Cylinder Diameter (mm) | Feed Particle Size (mm) | Working Pressure (MPa) | Minimum Circulation Rate (m³/h) | Processing Capacity (t/h) |

| 1200/850 | 1200 | 850 | ≤85 | 0.20-0.30 | 900 | 280-400 |

| 1100/780 | 1100 | 780 | ≤80 | 0.16-0.25 | 800 | 230-350 |

| 1000/700 | 1000 | 700 | ≤70 | 0.15-0.22 | 600 | 180-300 |

| 900/650 | 900 | 650 | ≤65 | 0.13-0.20 | 550 | 120-200 |

| 850/600 | 850 | 600 | ≤60 | 0.12-0.17 | 450 | 100-180 |

| 710/500 | 710 | 500 | ≤50 | 0.10-0.15 | 300 | 70-120 |

| 600/400 | 600 | 400 | ≤35 | 0.07-0.13 | 270 | 50-90 |

| 500/350 | 500 | 350 | ≤25 | 0.05-0.10 | 210 | 25-60 |

Shandong Xinjia Heavy Industry Technology Co., Ltd. stands as your trusted partner. We are committed to delivering reliable products, innovative technologies, and exceptional service support. By collaborating with you to tackle market challenges, we aim to achieve mutual success and leave a lasting mark on our journey of development, forging a brilliant future. With outstanding quality, cutting-edge technology, and premium services, our company has become an industry leader. In the heavy industry sector, Xinjia Heavy Industry leads the way by providing top-tier products and solutions that drive industry advancement. Together with our clients, we write remarkable chapters and shine brightly on the path ahead.