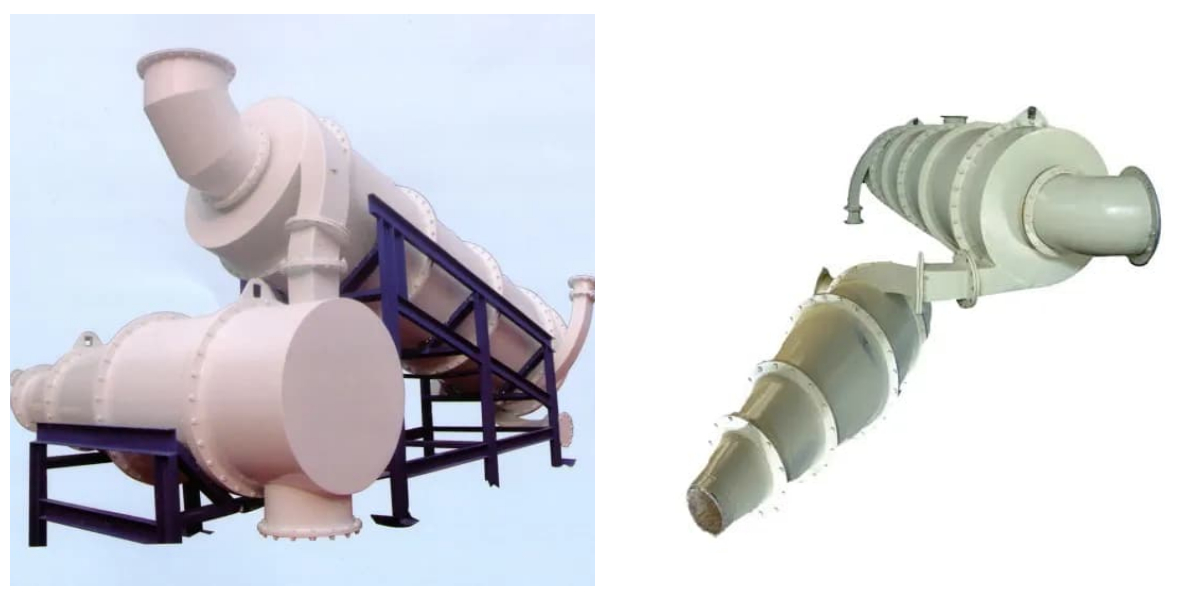

Heavy Medium Cyclone

Technical features:

High sorting efficiency: Clean coal, medium coal and gangue are sorted out in one go with a single low-density heavy medium, and the process system is simple and reliable.

Large processing capacity: High upper limit of feeding and strong gangue discharge capacity, suitable for materials with large variations in gangue content.

Strong wear resistance: Made of high-performance wear-resistant materials, it has a long service life.

Adjustable separation density: The separation density of the first and second stages can be adjusted online steplessly to meet the requirements of different coal qualities.

Energy conservation and consumption reduction: Pressureless feeding eliminates the need for pumping, reducing power consumption and equipment wear.

The pressureless feeding heavy medium cyclone is a highly efficient coal sorting equipment. It adopts a pressureless feeding method and utilizes the centrifugal force generated by the high-speed rotation of the heavy medium suspension within the cyclone to separate materials of different densities, thereby achieving coal sorting. This equipment features high sorting accuracy, large processing capacity, stable and reliable operation, and is widely used in industries such as coal, power and metallurgy.

Structural feature three:

Product sorting: It has three discharge ports and can simultaneously produce clean coal, medium coal and gangue.

Two-stage design: The first stage is cylindrical and the second stage is cylindrical conical, which improves the sorting accuracy.

Medium recycling: Heavy medium suspensions can be recycled, reducing operating costs.

Regular maintenance and cleaning: C

lear the internal sediment and debris to keep the equipment clean.

Check for wear: Regularly replace worn parts and inspect the sealing performance.

Lubrication and maintenance: Pay attention to the lubrication of the equipment and change the lubricating oil regularly.

| Specification | First-Stage Cylinder Diameter (mm) | Second-Stage Cylinder Diameter (mm) | Feed Particle Size (mm) | Working Pressure (MPa) | Medium Circulation Rate (m³/h) | Processing Capacity (t/h) | Installation Angle (°) |

| 1200/850 | 1200 | 850 | ≤85 | 0.13-0.25 | ≥1200 | 280-400 | 15-30 |

| 1100/780 | 1100 | 780 | ≤75 | 0.12-0.22 | 820-1000 | 230-350 | |

| 1000/700 | 1000 | 700 | ≤70 | 0.11-0.19 | 700-850 | 180-300 | |

| 900/650 | 900 | 650 | ≤65 | 0.10-0.17 | 520-680 | 130-240 | |

| 850/600 | 850 | 600 | ≤60 | 0.09-0.15 | 460-540 | 100-180 | |

| 700/500 | 700 | 500 | ≤50 | 0.08-0.13 | 260-350 | 70-120 | |

| 600/400 | 600 | 400 | ≤40 | 0.07-0.11 | 190-280 | 50-70 | |

| 500/350 | 500 | 350 | ≤35 | 0.06-0.10 | 130-150 | 25-50 |

Real photos of the installation site of production equipment at Shandong Xinjia Heavy Industry

Shandong Xinjia Heavy Industry Technology Co., Ltd. is committed to green development principles. Our energy-efficient products reduce resource consumption and environmental pollution. As a green pioneer in the heavy industry sector, Xinjia Heavy Industry helps clients achieve sustainable development, contributes to a beautiful planet, and co-creates a greener future. Specializing in high-efficiency production, our products deliver exceptional performance that significantly boosts productivity while lowering operational costs. In today's competitive market, Xinjia Heavy Industry stands as your expert in efficiency solutions, empowering businesses to grow rapidly and secure more business opportunities and profits.