Intelligent coal jigging equipment

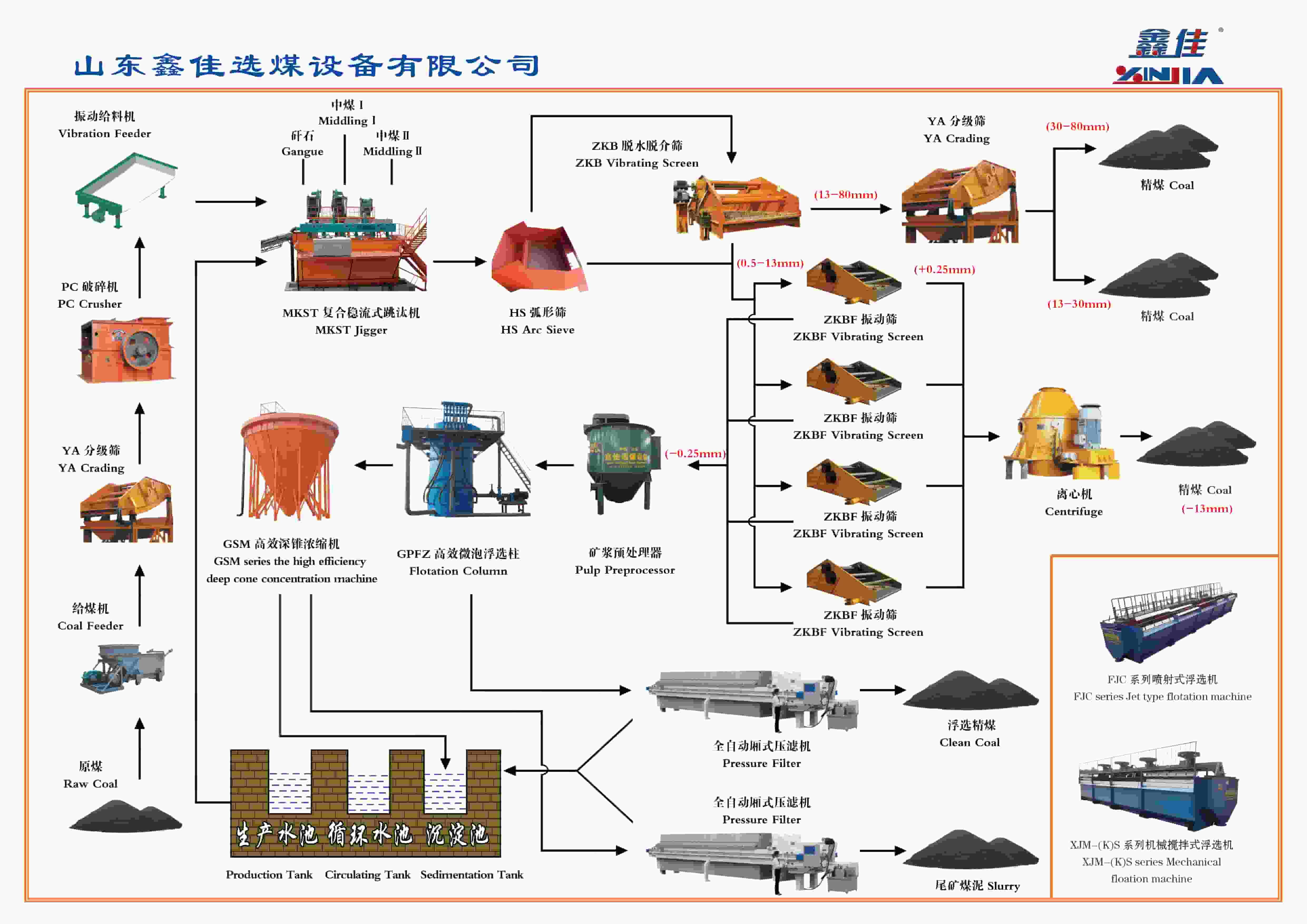

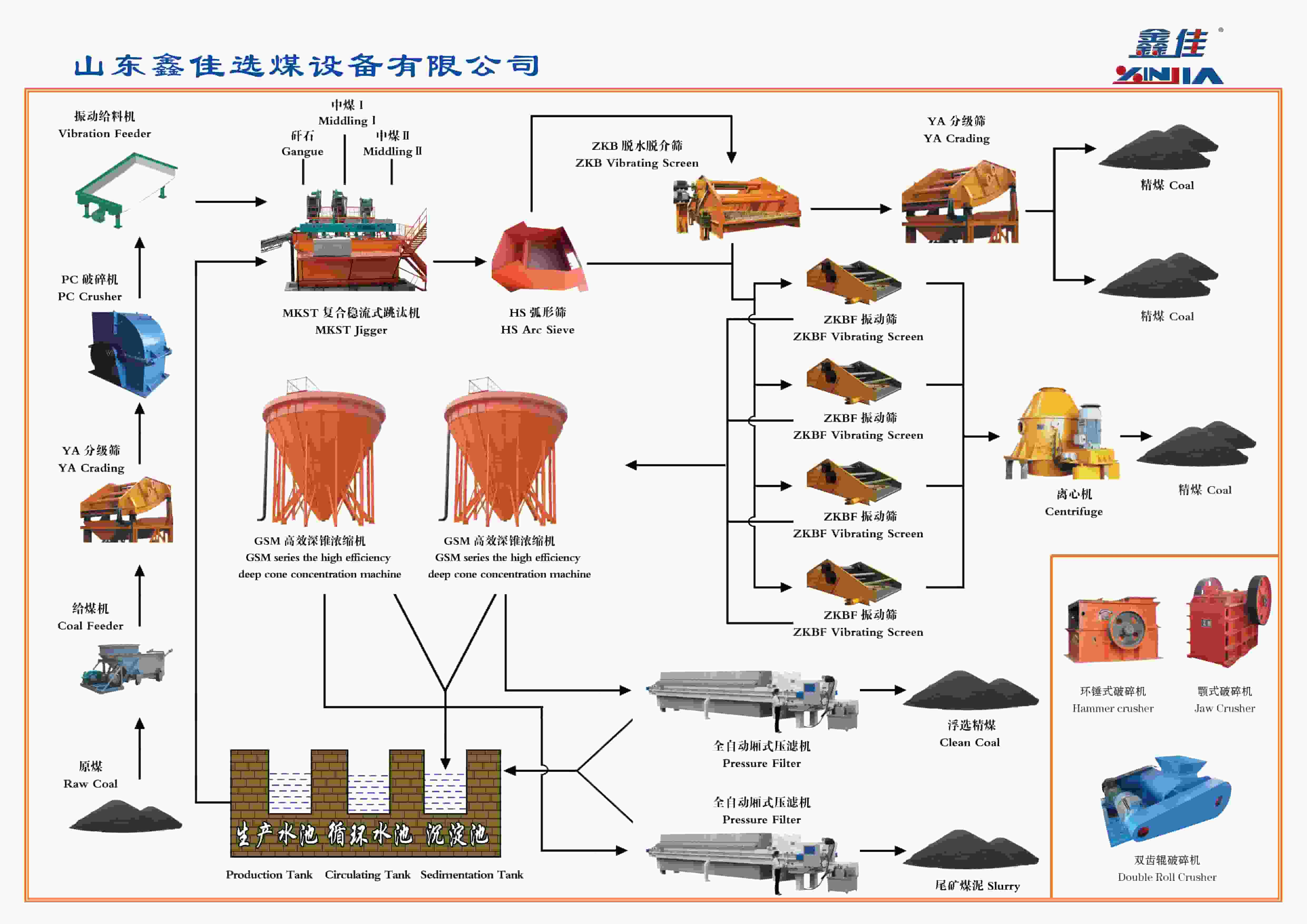

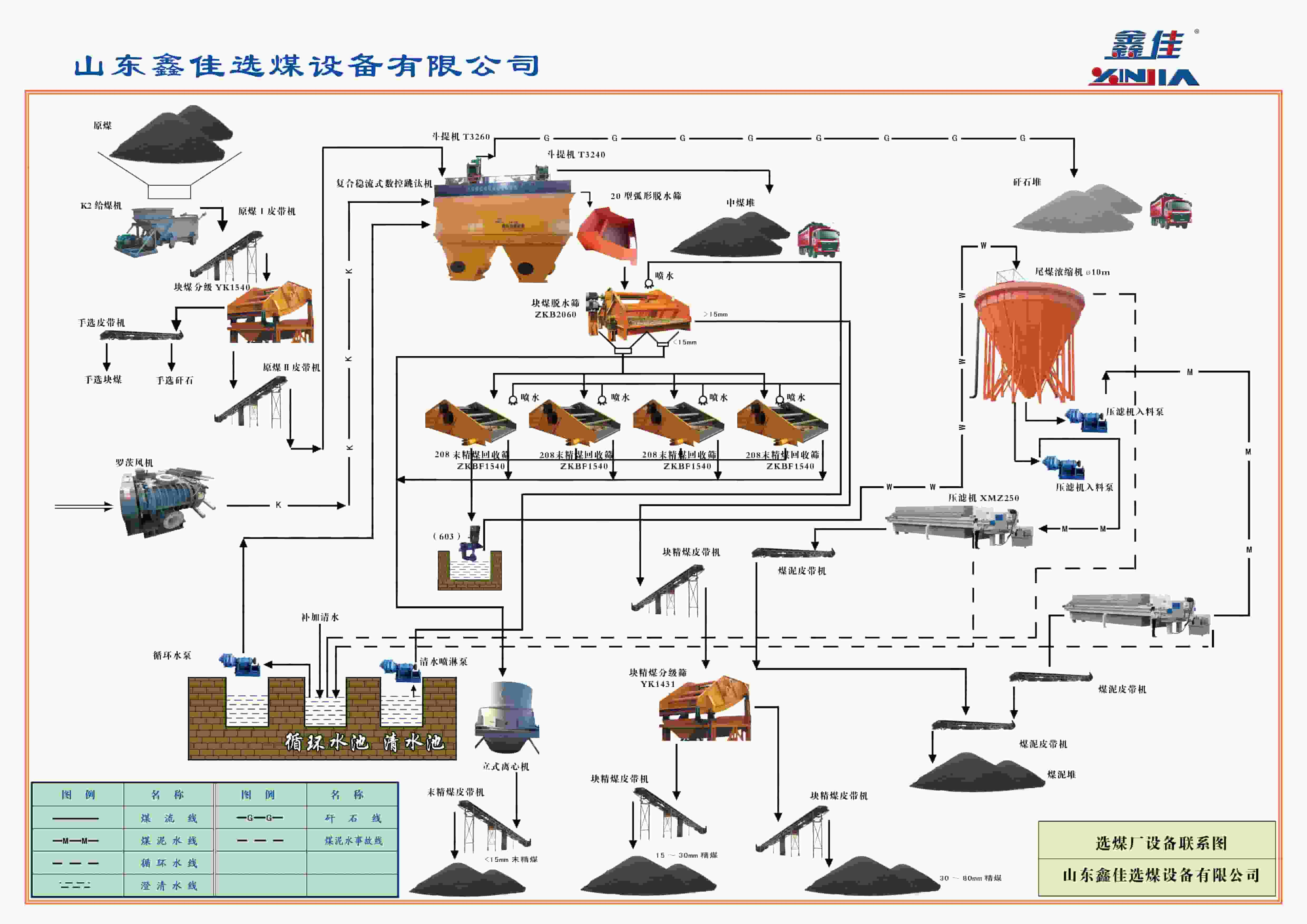

1.The coal preparation system is divided into subsystem modules including main washing system, flotation system, concentration and filtration system, and cargo handling system. It can be combined and specially designed based on any single subsystem module or multiple subsystem modules.

2.The product has a complete design system with high coal washing precision. The ash content of clean coal can reach 6-10%. The main washing process adopts numerical control system, and its unit area processing capacity is 20% higher than traditional processes.

3.The equipment features integrated steel structure assembly, occupying small space, with low power consumption. It doesn't require high-rise buildings, reducing total investment by about 50% compared to traditional processes of the same scale, and washing costs by about 60%, resulting in significant economic benefits.

4.The system has a high degree of mechanization, requiring fewer labor personnel, with convenient equipment installation and maintenance. The equipment performs stably with minimal maintenance requirements, allowing continuous production.

Our company's innovative MK/LTX series modular intelligent jigging coal preparation equipment represents a revolutionary breakthrough in the coal washing industry, completely transforming traditional coal washing plant equipment layout concepts.

Equipment Application Range: This equipment is designed for washing and selecting high-quality metallurgical coal, suitable for coal washing plants with an annual processing capacity of 15-500 million tons.

Washing and Separation Effect:

1.Clean Coal Ash Content: 6-10% (depending on raw coal characteristics)

2.Quantity Efficiency: 93-95% (depending on raw coal characteristics)

3.Clean Coal Moisture: 8-11% (depending on raw coal characteristics)

4.Desulfurization Rate: 80% for inorganic sulfur removal

5.The equipment's water circulation system achieves fully closed-loop circulation, with no wastewater discharge and no environmental pollution.

Main performance parameters of complete set of equipment for coal preparation by jigging process:

Model | Unit(sets) | Annual Washing Capacity (10,000 tons) | Equipped Power (KW) | Floor Area | Equipment Processing, Installation & Commissioning Period (days) | Washing Particle Size (mm) | Water Consumption per Ton of Coal (m³) | Power Consumption per Ton of Coal (kWh) | Remarks | |||

Main Equipment (m²) | Other (mu) | Processing Period | Installation Period | Commissioning Period | ||||||||

MKCT3-20 | Set | 20-25 | 208 | 470 | 10-20 | ∽40 | ∽30 | ∽5 | ≤50 | ∽0.1 | 2.5-3.5 | 1. Different process equipment is adopted according to different coal qualities and user requirements. |

299 | ||||||||||||

MKCT4-30 | Set | 25-30 | 218 | 480 | 15-25 | ∽40 | ∽30 | ∽5 | ≤50 | ∽0.1 | 2.5-3.5 | |

310 | ||||||||||||

MKCT5-40 | Set | 35-40 | 260 | 520 | 20-40 | ∽40 | ∽30 | ∽5 | ≤50 | ∽0.1 | 2.5-3.5 | |

365 | ||||||||||||

MKST6-50 | Set | 45-50 | 296 | 600 | 30-45 | ∽50 | ∽50 | ∽5 | ≤50 | ∽0.1 | 2.5-4 | |

415 | ||||||||||||

MKST8-60 | Set | 55-60 | 318 | 700 | 40-50 | ∽50 | ∽50 | ∽5 | ≤50 | ∽0.1 | 2.5-3.5 | |

450 | ||||||||||||

MKST10-80 | Set | 70-80 | 392 | 800 | 40-60 | ∽60 | ∽75 | ∽5 | ≤100 | ∽0.1 | 3-4 | |

528 | ||||||||||||

MKST/LTX12-100 | Set | 90-100 | 468 | 900 | 50-65 | ∽60 | ∽75 | ∽10 | ≤100 | ∽0.1 | 3-4 | |

580 | ||||||||||||

MKST/LTX14-120 | Set | 110-120 | 520 | 1000 | 50-70 | ∽60 | ∽85 | ∽10 | ≤100 | ∽0.1 | 3-4 | |

660 | ||||||||||||

MKST/LTX16-130 | Set | 120-130 | 640 | 1100 | 60-80 | ∽60 | ∽90 | ∽10 | ≤100 | ∽0.1 | 3-4 | |

960 | ||||||||||||

MKST/LTX20-160 | Set | 140-160 | 800 | 1300 | 60-80 | ∽60 | ∽90 | ∽10 | ≤120 | ∽0.1 | 3-4 | |

1160 | ||||||||||||

MKST/LTX24-180 | Set | 160-180 | 900 | 1500 | 80-90 | ∽75 | ∽100 | ∽15 | ≤120 | ∽0.1 | 3-4 | |

1360 | ||||||||||||

MKST/LTX26-200 | Set | 190-200 | 1040 | 2000 | 80-100 | ∽75 | ∽100 | ∽15 | ≤120 | ∽0.1 | 3-4 | |

1300 | ||||||||||||

MKST/LTX30-240 | Set | 210-240 | 2000 | 2500 | 100-120 | ∽75 | ∽120 | ∽20 | ≤120 | ∽0.1 | 3-4 | |

2800 | ||||||||||||

We adhere to the principle of "quality first, integrity first", committed to the pursuit of excellence in the creation of every product, treat every process with care, uphold the spirit of craftsmanship.

For years, Xinja Heavy Industry has upheld the service philosophy of "customer-centricity", delivering customized solutions for energy enterprises across over 20 provinces and cities in China, as well as Southeast Asia, with cumulative service to more than 500 clients. From equipment selection and installation commissioning to post-operation maintenance, Xinja provides comprehensive support throughout the entire process, earning widespread acclaim from customers.

Choosing Xinja Heavy Industry means choosing an efficient and reliable partner for energy equipment, working together to drive high-quality development in the energy sector!