coal separator

With powerful processing capabilities, up to 1000t/h, and a vibration frequency of 700-1500 times per minute, it is suitable for various large-scale industrial scenarios.

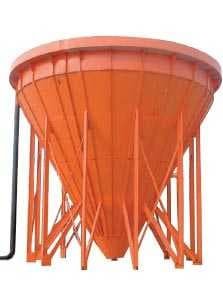

Adopting an upward-flow structure design, it reduces power consumption by 25% while improving screening efficiency, making it particularly suitable for moist materials with strong adhesion.

The modular design is equipped with polyurethane-edged screen plates and a dual-motor synchronous system, featuring anti-clogging functions. It can achieve real-time parameter monitoring through a digital system, ensuring convenient maintenance.

The sealed dust-proof cover design completely eliminates dust flying, improving the working environment; the equipment operates with low noise and has a long service life.

For wet coal and difficult-to-screen materials, high-frequency vibration is used to break the surface tension of the pulp, accelerating density separation and enhancing screening efficiency and dewatering effect.

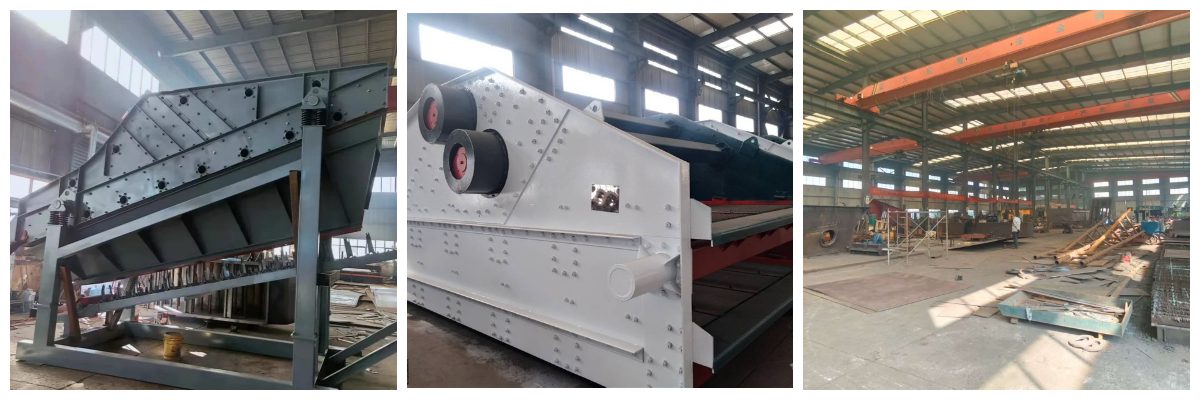

Single and double layer vibrating screens are composed of screening box, vibrator, elastic support device, flexible coupling and motor. The screening plate is made of stainless steel welded screening plate, perforated screening plate or rubber screening plate with long rectangular hole or square hole.

Single-layer screens are renowned for their simplicity, efficiency, and low maintenance costs. In contrast, double-layer screens have significant advantages in grading accuracy and processing capacity, making them suitable for high-capacity, multi-stage screening requirements.

The eccentric shaft is driven by a vibrating motor, causing the screen box to move in a straight line or circular motion. Materials jump forward on the screen surface, and particles smaller than the screen holes pass through the screen mesh, achieving efficient classification

It is applicable to raw coal and various ores, building materials, chemicals and other granular materials, especially performing exceptionally well for wet, sticky and difficult-to-screen materials

| Model | Area (m²) | Motor Power (Kw) | Sieve Aperture (mm) | Feed Particle Size (mm) | Vibration Frequency | Amplitude (mm) |

| YK1540 | 6 | 7.5 | ≤50 | ≤200 | 960 | 6-9 |

| YK1740 | 6.8 | 11 | ≤50 | ≤200 | 960 | 6-9 |

| YK1848 | 8.64 | 11 | ≤50 | ≤200 | 960 | 6-9 |

| 2YK1540 | 6 | 11 | ≤50 | ≤200 | 960 | 6-9 |

| 2YK1740 | 6.8 | 11 | ≤50 | ≤200 | 960 | 6-9 |

| 2YK1848 | 8.64 | 15 | ≤50 | ≤200 | 960 | 6-9 |

| 2YK2060 | 12 | 22 | ≤50 | ≤200 | 960 | 6-9 |

| 2YK2460 | 14.4 | 30 | ≤50 | ≤200 | 960 | 6-9 |