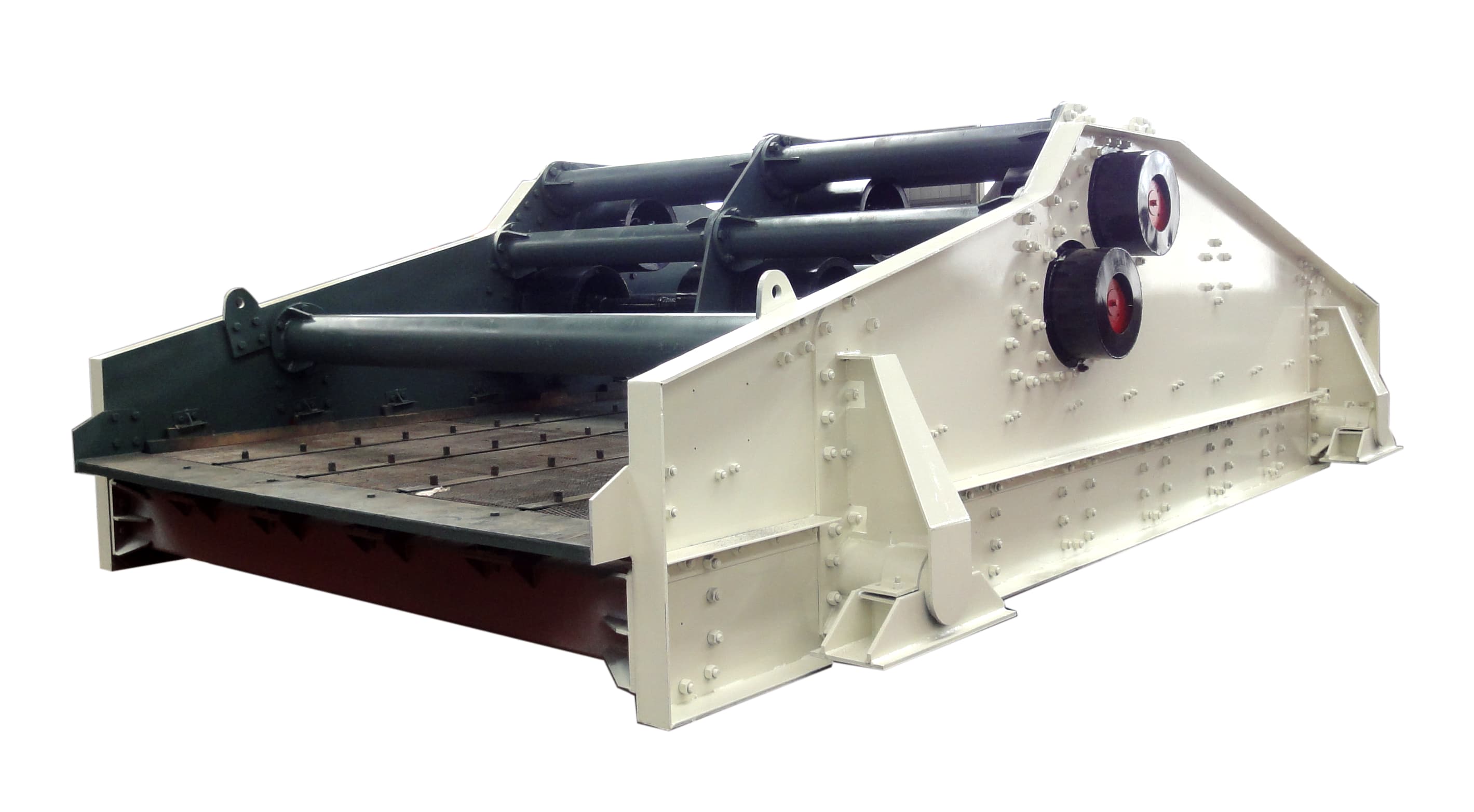

Hyperstatic Vibrating Screen

The statically indeterminate grid beam vibration structure large-scale vibrating screen is a superior product of Shandong Xinjia Heavy Industry Technology Co., Ltd.

The large vibrating screen products with hyperstatic grid beam excitation structure manufactured by Shandong Xinjia Heavy Industry Technology Co., Ltd. occupy an important position in the market with their outstanding advantages. Firstly, as a patented product, it possesses unique technology and innovative design, ensuring its leading position in the industry. Secondly, being a domestic pioneer, it demonstrates the company's strong capabilities in technological research and innovation. The adoption of the new grid beam structure not only improves product performance but also provides users with a more stable and efficient screening experience. This product can replace imported products, demonstrating its excellent cost-effectiveness and technical strength, making it the preferred choice in the domestic market. Finally, as a large vibrating screen, it performs exceptionally well in handling various material screening tasks and is widely used in multiple industries, earning high user trust and praise.

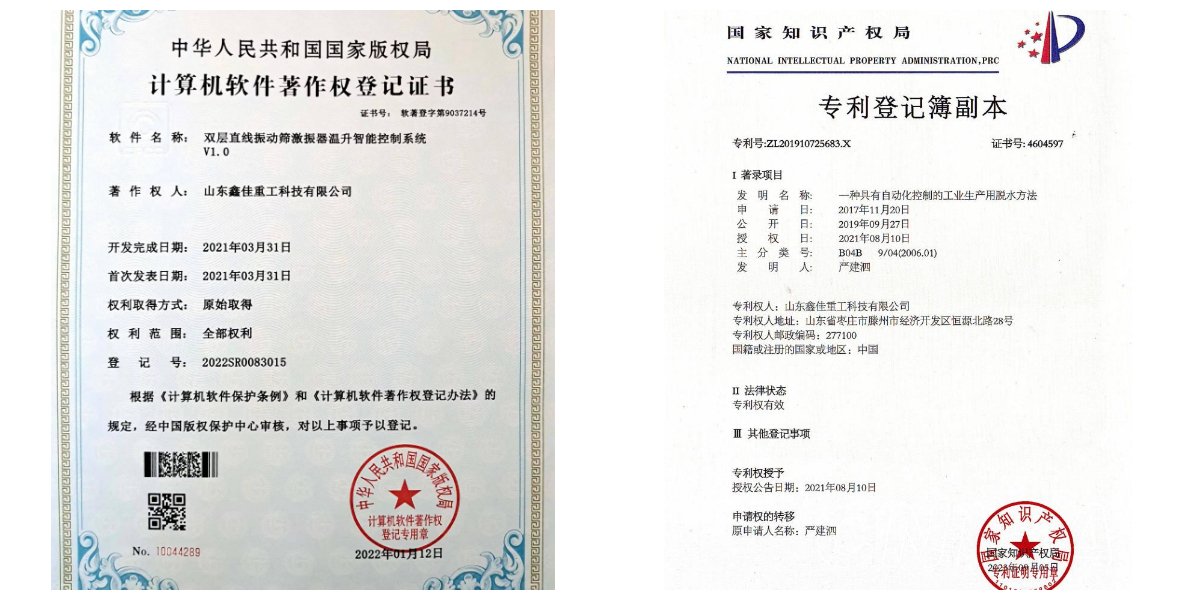

I. Patented Product: Legal Safeguard and Performance Endorsement of Cutting-edge Technology

This product holds a national invention patent, with its core innovations having been confirmed through intellectual property rights. The patent-protected statically indeterminate mesh beam device adopts a composite structure of "multiple main beams + statically indeterminate support plates," eliminating the need for traditional I-beam supports. This reduces the exciter’s volume by over 30%, lowers the vibrating mass by 25%, and increases the excitation force transmission efficiency to over 90%. This patented technology not only avoids the risk of structural plagiarism but also, as verified by finite element analysis, ensures that under a working frequency of 12.2 Hz, the maximum stress on the screen body is only 15.495 MPa—far below the 30 MPa threshold of traditional structures—providing dual assurance in both legal and data terms for the equipment’s long-term stable operation.

II. Domestic First: Industry Breakthrough Breaking Technological Monopoly

As the first statically indeterminate mesh beam excitation vibrating screen in China to achieve industrial application, its technical approach fills the gap in large-scale domestic vibrating screens. Compared to traditional single-channel/dual-channel structures, this product introduces, for the first time, the theory of statically indeterminate structures from theconstruction field into screening equipment. Through "redundant constraint design," the screen body maintains geometric stability even if a single constraint is compromised, enhancing its resistance to sudden damage by over 40%.

III. New Mesh Beam System Structure: Reconstructing the Performance Foundation of Large Screens

1. Structural Design Innovation

Adopting a coupled structure of "6 tube beams + 2 exciter beams + statically indeterminate support plates," it forms a high-rigidity inclusive excitation element. The lateral rigidity is increased by 30% compared to traditional dual-channel structures, solving the challenge of "insufficient rigidity caused by width expansion" in large screens. By adding baffle plates and peripheral reinforcing ribs, the lateral deformation of the screen body is reduced from 0.428 mm to 0.126 mm, achieving top-tier industry precision in deformation control.

2. Dynamic Performance Optimization

The natural frequency, optimized through modal analysis, is kept far from the 12.2 Hz working frequency, completely avoiding resonance risks and reducing the equipment failure rate by over 60%. Compared to single-channel structures, its bending-torsion deformation natural frequency is increased by 50%, maintaining vibration stability even in large models with a 3.6 m screen width, with noise controlled below 85 dB.

IV. Imported Product Alternative: Dual Superiority in Cost-performance and Adaptability

1. Technical Specifications Aligned with International Standards

It achieves "catch-up and surpassing" of imported equipment in core performance: screening efficiency reaches 90% (typically 85%-88% for imported equipment), service life exceeds 5 years (around 4-5 years for imported equipment), while the price is only half that of similar imported products.

2. Localization Adaptation Advantages

Tailored to the characteristics of high-ash and high-viscosity raw coal in China, the excitation parameters and screen inclination angle are optimized, reducing hole-blocking rates to below 5% (typically 10%-15% for imported equipment). Meanwhile, spare parts supply cycles are shortened to 7-15 days, far better than the 3-6 months of imported equipment, and maintenance costs are reduced by over 40%.

V. Large Vibrating Screens: Key Equipment Solving Industry Expansion Challenges

1. Specification Breakthrough and Capacity Upgrade

It enables large-scale designs with a screen width of 3.0-3.6 m and a screen surface area of over 21.6 m², with a single-unit processing capacity increased by 30%-50% compared to traditional equipment, meeting the raw coal classification needs of large mines with annual outputs of over 12 million tons. By adopting a multi-exciter series connection, it solves the issue of "insufficient excitation force due to large-scale design," achieving an excitation intensity of 5.0 g to meet the stringent requirements of dry deep screening.

2. Structural Reliability Assurance

Through the stress dispersion design of the statically indeterminate mesh beam structure, the peak stress on the screen body during full-load operation is reduced by 20%, completely resolving the common issues of "tube beam fractures and side plate cracks" in traditional large screens. Application data from coal preparation plants in multiple provinces, such as Yunnan and Shanxi, show that the equipment operates continuously without failure for over 8,000 hours—far exceeding the industry average standard of 5,000 hours.

| No. | Screen Model | Screen Surface Specification (W×L) (mm) | Screen Surface Area (m²) | Number of Screen Layers (Layer) | Screen Mesh Size (mm) | Screen Surface Inclination (°) | Double Amplitude (mm) | Frequency (Hz±0.4) | Feed Particle Size (mm) | Processing Capacity (t/h) | Motor Model | Power (KW) | Total Weight (Kg) |

| 1 | CSWS3048 | 3000×4800 | 14.4 | 1 | 0.25-50 | 0±5 | 6-11 | 12.2-15 | 0-100 | 80 | Y180L-6 | 15×2 | 10280 |

| 2 | CSWS3060 | 3000×6100 | 18.3 | 1 | 0.25-50 | 0±5 | 6-11 | 12.2-15 | 0-100 | 100 | Y200L1-6 | 18.5×2 | 11980 |

| 3 | CSWS3648 | 3600×4800 | 17.28 | 1 | 0.25-50 | 0±5 | 6-11 | 12.2-15 | 0-100 | 100 | Y180L-6 | 15×2 | 12000 |

| 4 | CSWS3661 | 3600×6100 | 21.96 | 1 | 0.25-50 | 0±5 | 6-11 | 12.2-15 | 0-100 | 130 | Y200L1-8 | 18.5×2 | 14660 |

| 5 | CSWS3675 | 3600×7500 | 27 | 1 | 0.25-50 | 0-35 | 6-11 | 12.2-15 | 0-300 | 1200 | Y200L1-8 | 18.5×2 | 16850 |

Shandong Xinjia Heavy Industry Technology Co., Ltd. crafts timeless excellence through meticulous craftsmanship. We pursue perfection in every detail to ensure superior product performance. By choosing Xinjia Heavy Industry, you embrace the legacy of artisanal quality that delivers reliable support for your production operations and builds remarkable achievements. Innovation-driven excellence at Shandong Xinjia Heavy Industry Technology Co., Ltd. continuously elevates product standards through technological advancement. By blending innovation with quality, we deliver exceptional heavy industry solutions tailored for our clients.