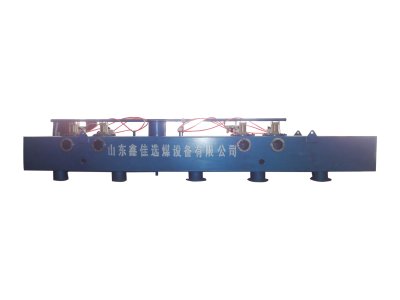

Elastic Rod Vibrating Screen

This screen adopts a multi-degree-of-freedom elastic rod impact screen. The frame structure features clearance fit without constraints between the elastic rods and the screen plate frame walls. This screen structure has high stiffness, durability, and can adapt to different material processing requirements.

Application Range: Suitable for classifying sticky and wet materials with particle size above 3mm in industries such as coal, mining, power, and chemical engineering.

Main technical parameters of STKB series elastic rod vibrating screens:

| sieve grade model | Mesh size | Feed particle size mm | Sieve mesh knot Broussonetia papyrifera | Operating frequency Hz | Single amplitude mm | Processing capacity T/h | Electric motor | Screen machine weight Kg | Fulcrum working dynamic load ±N | Maximum dynamic load at fulcrum ±N | |

| Upper level | Lower layer | ||||||||||

| 2S TKB1540 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 13-30 | Y132M1-6 | 2750 | 750 | 3750 |

| 50-95 | |||||||||||

| 2S TKB1556 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 15-35 | Y132M2-6 | 3100 | 1000 | 5000 |

| 60-110 | |||||||||||

| 2S TKB1740 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 20-48 | Y132M2-6 | 3500 | 1125 | 5625 |

| 80-150 | |||||||||||

| 2S TKB1856 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 16-32 | Y132M2-6 | 3200 | 1000 | 5000 |

| 65-120 | |||||||||||

| 2S TKB2050 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 22-45 | Y132M2-6 | 3700 | 1250 | 6250 |

| 85-160 | |||||||||||

| 2S TKB2160 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 45-90 | Y180L-6 | 12460 | 4600 | 23000 |

| 170-320 | |||||||||||

| 2S TKB2450 | 10-50 | 6-25 | 0-150 | Determined according to material characteristics | 16.2 | 3-5 | 54-126 | Y225M-8 | 14600 | 5350 | 26750 |

| 216-396 | |||||||||||

We adhere to the principle of "quality first, integrity first", committed to the pursuit of excellence in the creation of every product, treat every process with care, uphold the spirit of craftsmanship.

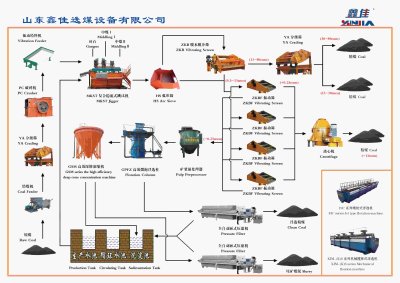

In the coal washing and coal mining equipment manufacturing industry, Shandong Xinjia Heavy Industry Technology Co., Ltd. has become an important driving force for technological advancement in the sector, thanks to its strong R&D capabilities and independently owned invention patents. The company consistently takes customer needs as its starting point, developing high-performance, intelligent energy equipment to help enterprises improve production efficiency.

To address environmental protection requirements in the coal washing process, the company has developed enclosed coal washing equipment that effectively reduces dust emissions, meeting national environmental standards. Meanwhile, its underground coal mine support equipment utilizes high-strength alloy materials combined with intelligent adjustment functions to enhance safety during underground operations. The design of each product combines practicality with innovation.