Straight dehydrating desiccator

The sieve type adopts eccentric block vibrator or box vibrator, self-synchronous vibration mode, low noise, reliable operation and convenient maintenance.

Featuring dual-motor driven self-synchronization technology, it provides stable and powerful excitation force, enabling materials to perform reciprocating linear motion on the screen surface, which allows for fast and effective dewatering, medium removal, and desliming. Some linear dewatering and medium removal screens adopt a V-shaped screen surface design.

The overall structure is simple, lightweight, and easy to install and maintain. The exciters are mostly of eccentric shaft or block eccentric structure. For example, Dahua Heavy Industry's linear dewatering screen adopts an advanced auxiliary block eccentric structure, which allows for very convenient replacement and disassembly. By adding or removing counterweight blocks, the appropriate amplitude can be easily adjusted.

The vibration frequency can be adjusted at any time via the inverter to achieve optimal dewatering performance, meeting the processing needs of materials with different properties.

Suitable for dehydration, dewatering, desintercalation and classification of cleaned products in coal washing plants.

It adopts dual-motor driven self-synchronization technology. The vibrator is dragged by a flexible coupling. When the two sets of vibrators rotate synchronously in opposite directions, the exciting forces generated by their eccentric blocks cancel each other out in the direction parallel to the motor axis and are superimposed into a resultant force in the direction perpendicular to the motor axis, thereby forming a single exciting force along the vibration direction, causing the screen box to make reciprocating linear motion. The material is thrown up and jumps forward on the screen surface to make a linear motion, and at the same time, the dehydration and de-mediation effects are achieved.

It mainly consists of a screen box, vibrators, a support system, and an electric motor. The screen box is the main component that carries the material and performs the screening function. The vibrators provide the vibrating power, the support system is used to hold up the screen box, and the electric motor supplies power to the vibrators.

| NO. | Screener Model | Sieve Aperture Size (mm) | Sieve Surface Structure | Feed Particle Size (mm) | Operating Frequency (Hz) | Single Amplitude (mm) | Processing Capacity (T/H) | Motor |

| 1 | ZKB1856 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 14-100 | Y160L-6 |

| 2 | ZKB2060 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 16-130 | Y180L-6 |

| 3 | ZKB2460 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 18-160 | Y180L-6 |

| 4 | ZKB2660 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 20-170 | Y200L1-6 |

| 5 | ZKB2860 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 22-180 | Y200L1-6 |

| 6 | ZKB3060 | 0.25-13 | Slotted | 0-150 | 16.2 | 3-5 | 27-190 | Y200L2-6 |

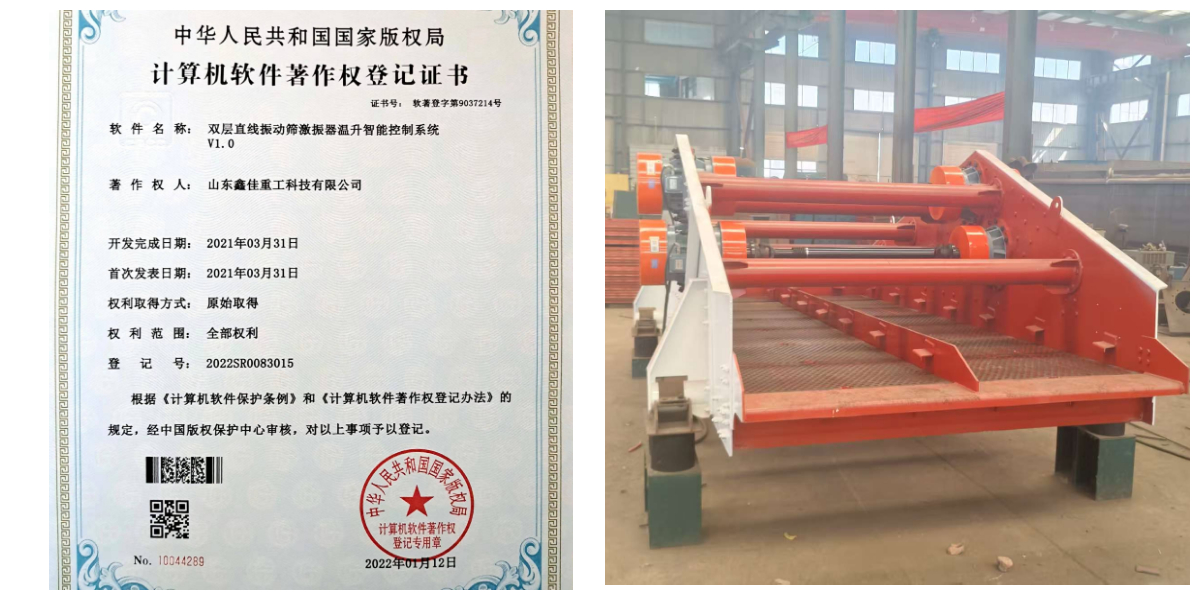

Shandong Xinjia Heavy Industry's linear dewatering and medium separation screen is equipped with independent patented technology, which achieves bidirectional wear through screen box flipping design, greatly extending its service life. Adhering to the spirit of craftsmanship in production, from CNC precise material cutting, argon arc welding for frame reinforcement, to three-coordinate measuring instrument calibration of screen surface accuracy, every process is strictly controlled to create efficient screening equipment.