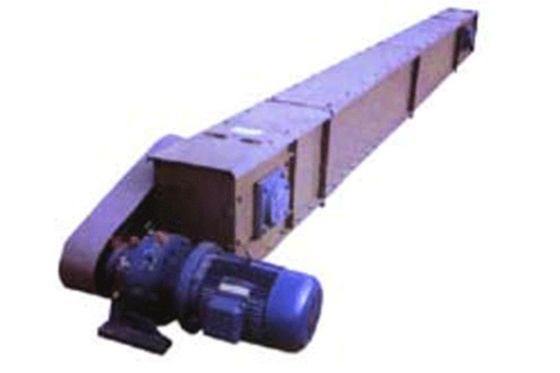

Scraper conveyor

Scraper conveyors are commonly used in coal mining for the transportation of bulk materials, especially in underground mining operations. These conveyors have several advantages and key features that make them suitable for handling coal in challenging mining environments.

Advantages of scraper conveyors in coal mining applications include:

Robust construction: Scraper conveyors are built to withstand the harsh conditions in coal mines, making them durable and reliable for continuous operation.

Efficient material handling: The design of scraper conveyors allows for the effective transport of bulk materials, including coal, over long distances and rough terrain.

Low maintenance requirements: With fewer moving parts and simple design, scraper conveyors have reduced maintenance needs, minimizing downtime and associated costs.

Versatility and flexibility: Scraper conveyors can be easily customized to suit specific application requirements, such as varying capacity and speed, making them versatile for different coal mining processes.

Key features of scraper conveyors used in coal mining include:

Scraper chain: The use of a robust scraper chain with paddles ensures reliable material transport and prevents spillage during the conveying process.

Drive mechanism: Scraper conveyors are typically equipped with efficient drive systems that provide the necessary power to move coal materials effectively.

Tensioning system: An adjustable tensioning system maintains proper chain tension, optimizing the performance and longevity of the conveyor.

Safety features: Scraper conveyors often come with safety features such as emergency stop buttons and protective guards to ensure the safety of operators and prevent accidents.

Overall, the advantages and key features of scraper conveyors make them a valuable and efficient solution for coal mining operations, contributing to the seamless transport of coal materials throughout the mining process.