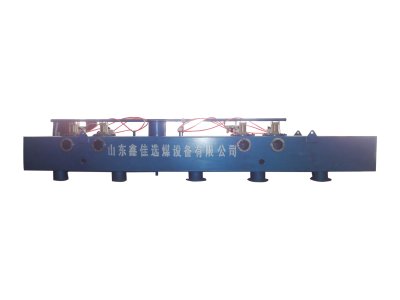

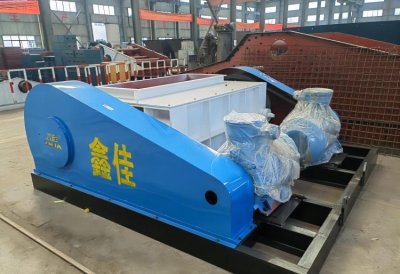

Electric vibrating feeder

Superior vibration performance: smooth vibration, reliable operation, and long service life; Low noise, low power consumption, good regulating performance, and no material flushing phenomenon.

Convenient control and adjustment,The structural design is excellent.,Environmentally friendly sealing performance.

It features high transportation efficiency, wide adaptability and is convenient for later maintenance and upkeep

Electromagnetic vibrating feeders are commonly used in coal mines for precise and controlled feeding of coal materials to other processing equipment. These feeders utilize electromagnetic vibrations to convey and distribute coal particles efficiently and accurately.

The primary uses and advantages of electromagnetic vibrating feeders in coal mining applications include:

Accurate and consistent feeding: Electromagnetic vibrating feeders provide a precise and uniform flow of coal materials, ensuring consistent feeding rates and optimal process control.

Adjustable feed rates: The feed rate of electromagnetic vibrating feeders can be easily adjusted to match the requirements of downstream equipment, allowing for flexible operation and enhanced efficiency.

Energy-efficient operation: These feeders consume less power compared to other types of feeders, making them a cost-effective solution for coal mining operations.

Low maintenance requirements: Electromagnetic vibrating feeders have fewer mechanical parts, resulting in reduced maintenance needs and increased equipment reliability.

Mild handling of materials: The gentle electromagnetic vibrations generated by these feeders help to maintain the integrity of the coal materials being fed, reducing the risk of degradation or segregation.

Overall, electromagnetic vibrating feeders play a crucial role in coal mining operations by enabling precise and controlled feeding of coal materials, leading to improved process efficiency, reduced downtime, and enhanced overall productivity.