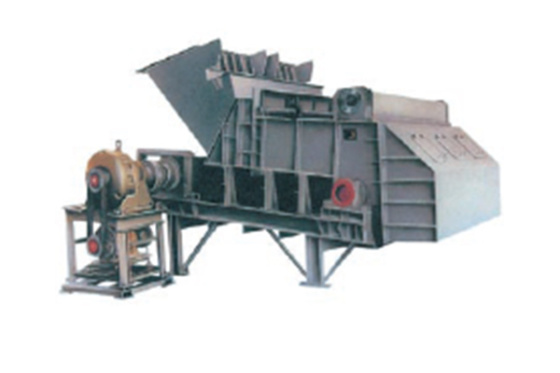

chain feeder

The LG type chain feeder is an ideal feeding equipment for jigs, characterized by uniform feeding along the entire width of the jigs, making it very suitable for feeding large and medium-sized jigs. The feeding amount can be easily adjusted according to needs, using frequency conversion speed regulation, and the feeding amount can be infinitely adjusted to achieve automatic feeding. Pre wetting can be applied to the raw coal entering the jigs to prevent clumping and improve the sorting efficiency of the jigs.

Chain feeders, also known as chain plate feeders, offer several advantages and key features that make them well-suited for various material handling applications:

Advantages:

Robust and durable construction: Chain feeders are typically built with strong, heavy-duty materials, making them capable of handling heavy and abrasive materials reliably.

Continuous and uniform feeding: The chain plate design enables a consistent and even material flow, helping to prevent clogging and ensure smooth operation.

Adjustable speed and feed rate: Chain feeders often have variable speed controls, allowing operators to adjust the feed rate according to the specific requirements of the material being handled.

Versatile applications: Chain feeders can be used in a wide range of industries, including mining, construction, agriculture, and more, making them a versatile solution for material feeding needs.

Key features:

Chain plates: The chain plates themselves are a distinctive feature of chain feeders, providing a durable and reliable surface for material transport.

Sprockets and chains: These components work together to drive the chain plates, ensuring smooth and continuous material feeding.

Adjustable design: Chain feeders can often be customized or adjusted to meet specific application requirements, such as adjusting the height or angle of the feeder.

Low maintenance requirements: With fewer moving parts compared to other types of feeders, chain feeders are generally easier to maintain, reducing downtime and maintenance costs.

Overall, chain feeders offer a reliable and efficient solution for material feeding applications, particularly in industries where heavy-duty and continuous material handling is required.

Chain feeders, also known as chain plate feeders, offer several advantages and key features that make them well-suited for various material handling applications:

Advantages:

Robust and durable construction: Chain feeders are typically built with strong, heavy-duty materials, making them capable of handling heavy and abrasive materials reliably.

Continuous and uniform feeding: The chain plate design enables a consistent and even material flow, helping to prevent clogging and ensure smooth operation.

Adjustable speed and feed rate: Chain feeders often have variable speed controls, allowing operators to adjust the feed rate according to the specific requirements of the material being handled.

Versatile applications: Chain feeders can be used in a wide range of industries, including mining, construction, agriculture, and more, making them a versatile solution for material feeding needs.

Key features:

Chain plates: The chain plates themselves are a distinctive feature of chain feeders, providing a durable and reliable surface for material transport.

Sprockets and chains: These components work together to drive the chain plates, ensuring smooth and continuous material feeding.

Adjustable design: Chain feeders can often be customized or adjusted to meet specific application requirements, such as adjusting the height or angle of the feeder.

Low maintenance requirements: With fewer moving parts compared to other types of feeders, chain feeders are generally easier to maintain, reducing downtime and maintenance costs.

Overall, chain feeders offer a reliable and efficient solution for material feeding applications, particularly in industries where heavy-duty and continuous material handling is required.