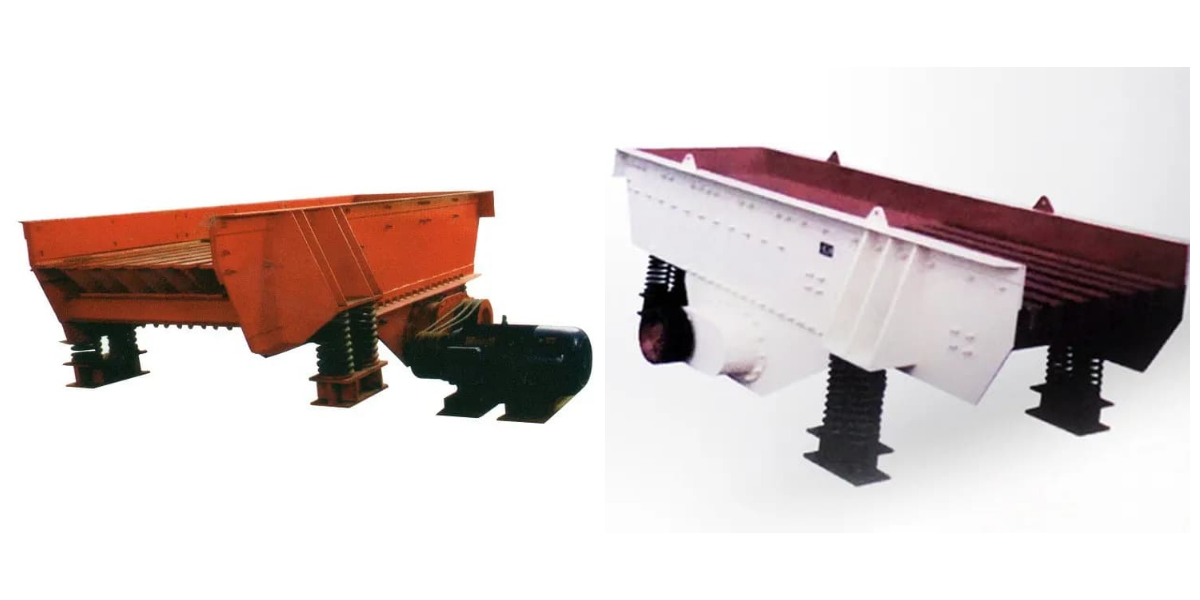

Vibrating Feeder

Smooth Vibration and Reliable Operation: Adopting a dual-shaft vibrator design, it ensures stable vibration without offset, offering a long service life of hours.

Uniform Feeding and Strong Adjustability: The excitation force or frequency can be adjusted at any time to achieve stepless flow regulation, facilitating automatic control .

Simple Structure and Easy Maintenance: With no complex rotating parts, installation and commissioning are convenient, and maintenance costs are low .

Energy-Saving and Environmental Protection: The enclosed structure prevents dust overflow, and the noise level is low (<75dB), meeting environmental protection standards .

Wear-Resistant and Impact-Resistant: The trough is made of high-strength manganese steel or wear-resistant liners, suitable for conveying large-sized materials .

Pre-Screening Function: The bar gap is adjustable, capable of separating fine materials and impurities to reduce the load on crushers.

A vibrating feeder is an industrial device used for uniform, timed, and continuous conveying of block, granular, and powdered materials. It is widely applied in industries such as metallurgy, coal mining, mineral processing, building materials, chemicals, and abrasives. It is typically installed before primary crushing equipment to continuously and uniformly feed materials into the crusher. Additionally, it has a coarse screening function, which can effectively prevent subsequent equipment from clogging due to uneven feeding, thereby improving overall production efficiency and automation level.

The vibratory feeder is mainly composed of the following core components:

Feeding trough: It carries the material and realizes vibration conveying.

Exciter: Composed of dual eccentric shafts (active and passive) and gear pairs, it generates a directional exciting force through motor drive.

Vibration motor: Acts as the exciting source to provide power.

Spring support: Buffers vibration and protects the equipment.

Transmission device: Includes V-belts, couplings, etc., used for power transmission.

Liner plate: Installed on the inner wall of the trough to enhance wear resistance; common materials include 16Mn manganese steel and high-molecular materials.

The device drives the eccentric shaft to rotate via an electric motor. The two shafts operate in reverse synchronization, generating periodic exciting forces that cause the trough to perform reciprocating vibrations along an inclined direction. When the vibration acceleration exceeds the gravitational acceleration, the material is thrown up and moves forward in a parabolic trajectory, achieving continuous and uniform feeding. By adjusting the exciting force or frequency, the feeding quantity can be precisely controlled.

| Model | Material Granularity (mm) | Processing Capacity (T/h) | Vibration Motor Power (kw) | Cloth Width (Bmm) |

| ZGM160*300 | 0-150 | 100-160 | 2.4*2 | 1600 |

| ZGM200*300 | 0-150 | 140-200 | 2.4*2 | 2000 |

| ZGM260*300 | 0-150 | 180-260 | 3.7*2 | 2600 |

| ZGM300*300 | 0-150 | 200-300 | 3.7*2 | 3000 |

Shandong Xinjia Heavy Industry Technology Co., Ltd. has earned market trust through its reliable quality. By collaborating with clients, we achieve mutual success. Moving forward, Xinjia Heavy Industry will continue to uphold the principle of quality supremacy, creating greater value for customers and jointly writing glorious chapters. As an industry benchmark, Xinjia Heavy Industry leads development trends by providing cutting-edge heavy industrial products and solutions. With its pioneering role, Xinjia Heavy Industry partners with clients to forge a brighter future and shine brightly in the industry.