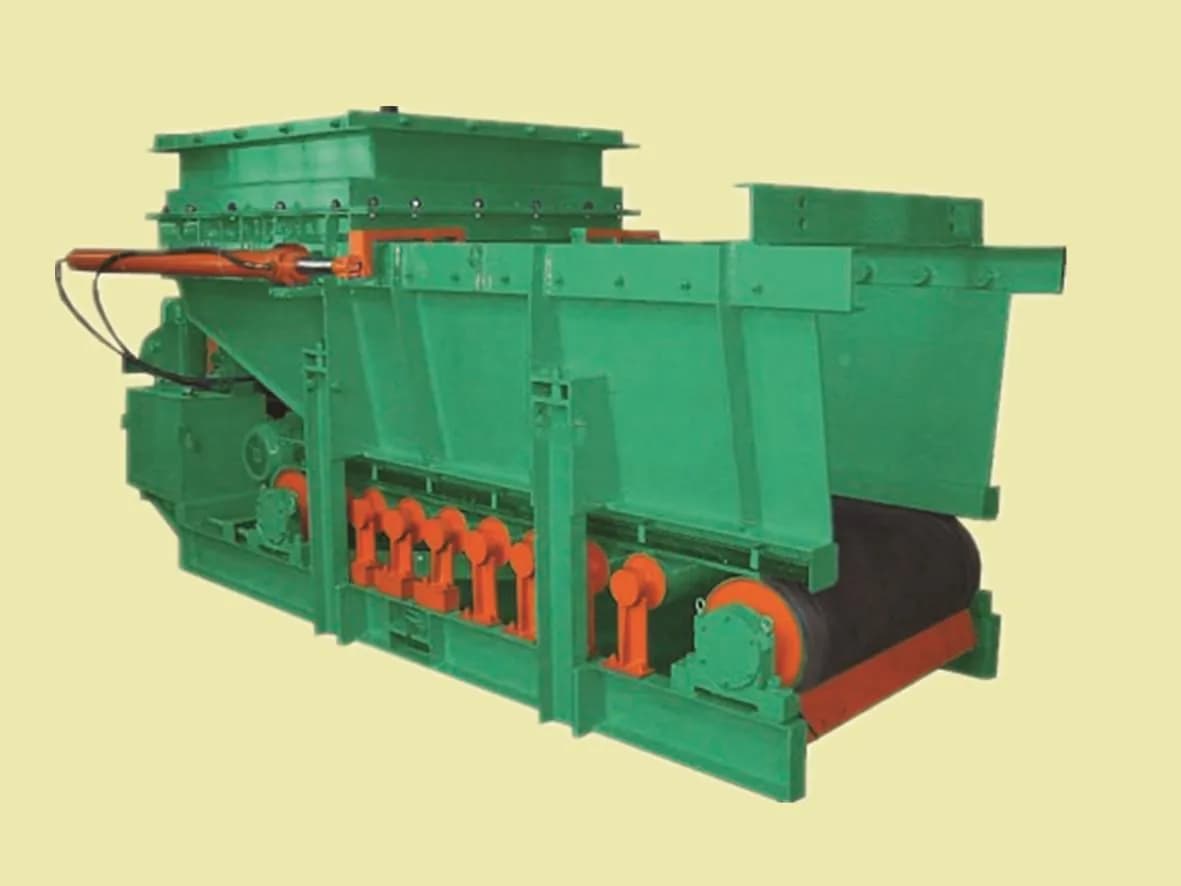

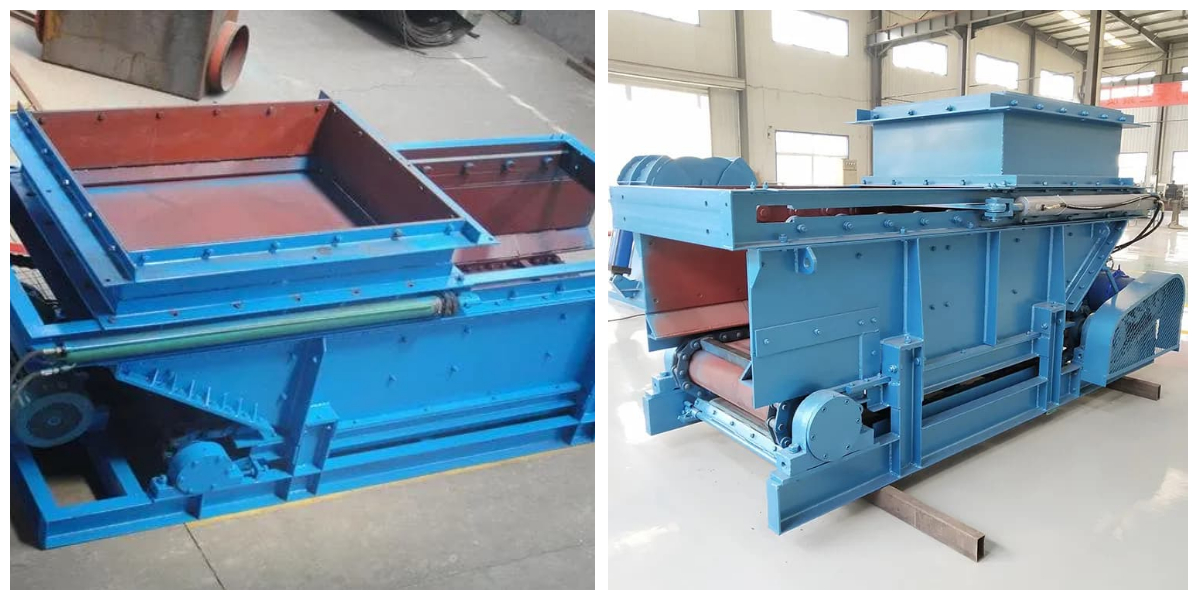

Chain Conveyor Feeder

Smooth and Durable Operation: The equipment operates smoothly with low noise, fast feeding speed, thick material layer, and large feeding capacity.

Continuous Adjustable Feeding Rate: By adjusting the speed control knob of the rotating arm planetary friction stepless speed changer or the frequency converter, the running speed of the conveyor belt or plate chain can be changed, thereby adjusting the feeding rate.

Strong Wear Resistance: High-wear-resistant liners are installed on the inner side of the feeding chute, making the equipment more durable and long-lasting.

Energy-Saving and Environmental Protection: Compared with reciprocating feeders, it has a smaller power consumption, good energy-saving effect, and low operating cost.

Strong Adaptability: It can convey materials with high temperature, large particle size, sharp edges, and strong abrasiveness.

Easy Maintenance: With a simple structure, it is convenient for installation, debugging, and maintenance, and has a long service life.

Chain feeder is a new type of feeding equipment developed specifically for the mining, steel and other industries. It is mainly used to replace traditional reciprocating feeders and is suitable for both surface and underground working environments. It can effectively solve the problem of equipment damage caused by materials such as raw coal, ore, and semi-coal-rock during the feeding process, especially reducing the belt damage rate, thereby ensuring the continuity and stability of material transportation.

The chain feeder drives the roller to run the plate chain or belt. The material enters the box through the hopper and funnel frame, falling onto the plate chain or belt. When the drive roller rotates, it drives the plate chain to move, and the scraper on the plate chain pushes the material towards the discharge port to complete the feeding process. The feeding quantity can be adjusted by regulating the speed of the output shaft of the stepless speed reducer or by changing the motor speed through a frequency converter.

| Model/Item | LG-16 | LG-18 | LG-21 | LG-24 | LG-27 | LG-30 | LG-36 |

| Feeding Trough Width (mm) | 1600 | 1800 | 2100 | 2400 | 2700 | 3000 | 3600 |

| Feeding Speed (m/s) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) | 0.08-0.24 (Inverter Speed Control) |

| Feeding Capacity (t/h) | 80-200 | 100-250 | 150-300 | 200-400 | 200-460 | 200-500 | 200-600 |

| Feeding Particle Size (mm) | 0-100 | 0-100 | 0-100 | 0-100 | 0-100 | 0-100 | 0-100 |

| Feeding Trough Horizontal Inclination (°) | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Number of Chains (pcs) | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

| Chain Pitch (mm) | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| Motor Power (kW) | 5.5 | 5.5 | 7.5 | 11 | 15 | 15 | 15x2 |

| Cycloidal Reducer Model | XW-8-71 | XW-8-71 | XW-9-71 | XW-9-87 | XW-9-87 | XW-11-87 | XW-11-87 |

| Matching Jig (㎡) | 6-8 | 8 | 10 | 14 | 16-18 | 200-500 | 24 |

Note: the feeder with trough width less than 1600mm can be designed and manufactured according to user's needs.

Xinjia Heavy Industry, Customer First, Service . Shandong Xinjia Heavy Industry Technology Co., Ltd. adheres to the philosophy of putting service first and takes customer needs as its guide. From product consultation to after-sales maintenance, it provides all-round high-quality services. Making customers satisfied is Xinjia Heavy Industry's pursuit, and becoming a trusted partner of customers to jointly open up a bright future together.