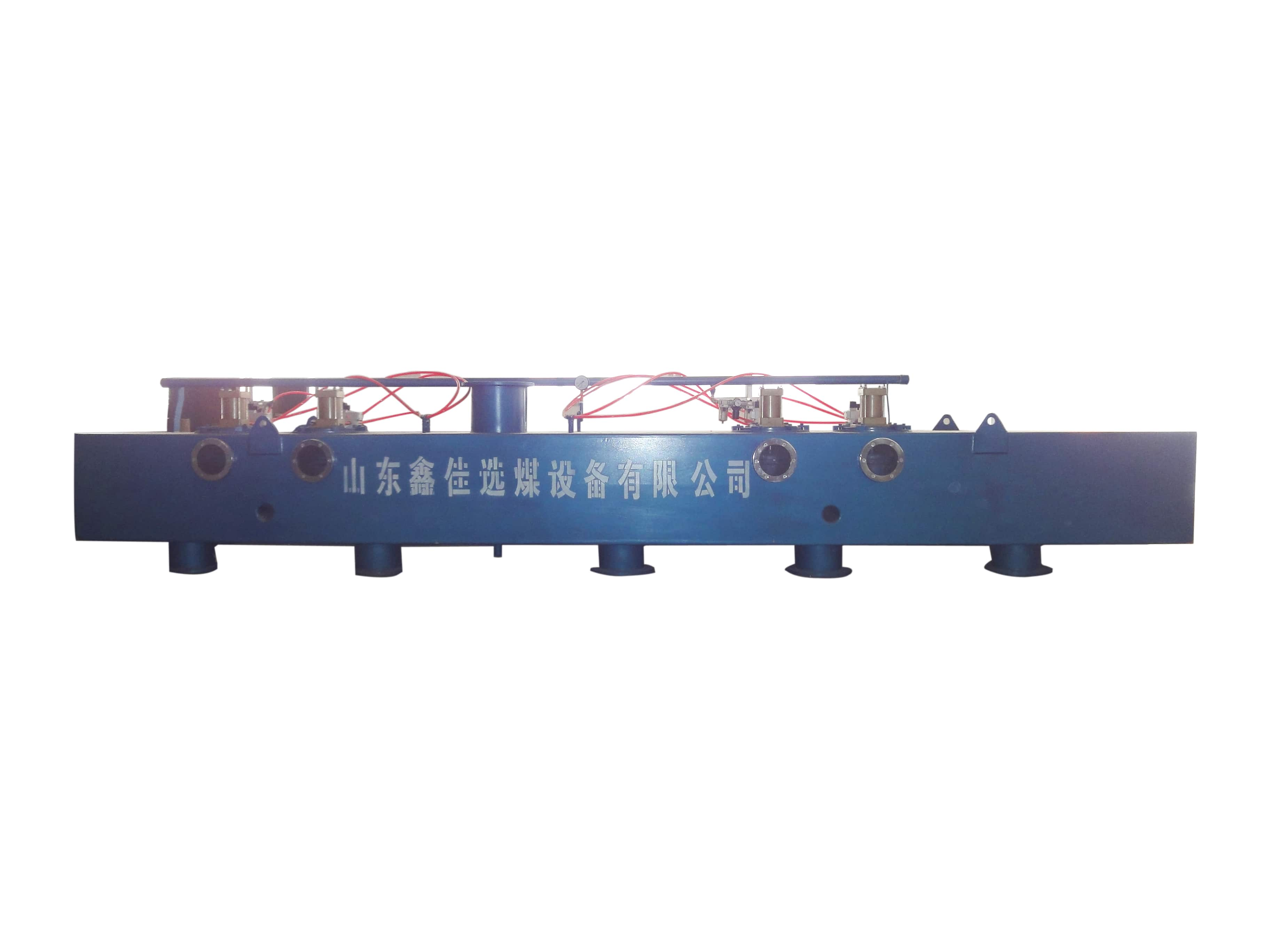

CNC Air Valve

1.Large Air Volume

2.Instant Air Intake and Exhaust

3.Low Maintenance

4. Low Power Consumption and Noise

5. Easy Upgradability

This air valve adopts a vertical rotating structure with multiple vertical ports for air intake and exhaust along the circumferential direction, resulting in large air intake and exhaust volume.The valve core operates with high rigidity and is less affected by environmental factors.

The valve core is supported on bearings, using rolling friction. The system does not need to overcome the gravity of the valve core, resulting in low resistance.The valve can be opened or closed within 0.05 seconds, with strong instantaneous explosive force.It can achieve more timely and accurate bed layer stratification, improving coal separation quality.

Key parts of this air valve use imported components, ensuring high reliability.

This air valve system eliminates the need for high-pressure fans, triplets, solenoid valves, and cylinders, fundamentally overcoming the shortcomings of pneumatic air valves and achieving virtually maintenance-free operation.

The power required for the new vertical rotating air valve is only one-third of that for CNC pneumatic air valves.

High-pressure fans are both the power source for pneumatic air valves and one of the main noise sources in coal preparation plants. This new air valve eliminates high-pressure fans, reducing noise.

For existing pneumatic CNC air valve systems, only the air valve needs to be directly replaced, with no changes required to the original control system or operation habits.

For horizontal air valve systems, only the valve core and air box need to be replaced.

The system can be with our company's CNC system products if needed.

Installation and improvement processes can be completed quickly and easily, enabling rapid production.

Corporate Spirit Through Light and Shadow: An Outdoor Photography Portrait.

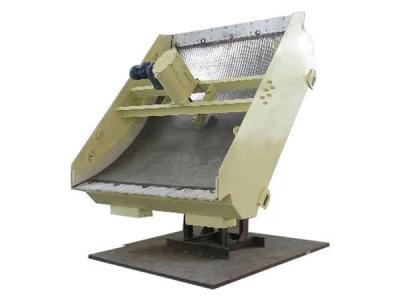

Xinjia's CNC Wind Valve for Jiggering Machines utilizes advanced numerical control technology to achieve precise opening and closing of the valve. Like intelligent hands, it flexibly adjusts according to material characteristics, ensuring stable and efficient jiggering processes while significantly improving sorting accuracy and efficiency. This guarantees optimal processing for every grain of coal and every mineral particle. Shandong Xinjia deeply understands the essence of quality.

The product is crafted from premium materials through meticulous manufacturing processes, featuring exceptional wear resistance and corrosion resistance. Even under harsh working conditions, it maintains stable operation like a robust fortress safeguarding smooth production lines, reducing maintenance costs for customers and creating long-term value.