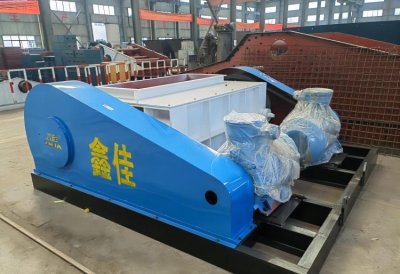

Double layer straight line dehydrating and desiccating screen

The upper screen can perform preliminary coarse screening of the material to separate large particles of impurities or coarse-grained products; the lower screen can perform fine screening or deep dehydration of fine-grained materials.

The effective screening area of the double-layer screen is nearly doubled that of the single-layer screen, and more materials can be processed per unit time.

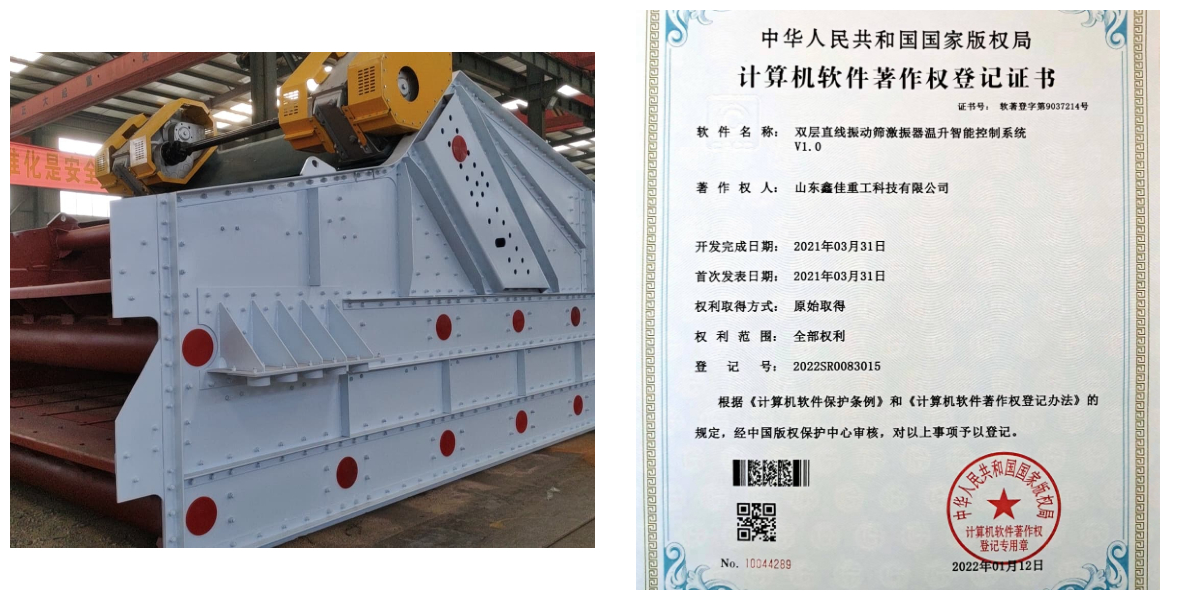

The vibration system of the double-layer screen adopts a dual-motor self-synchronization technology, reducing energy consumption by 15–20% compared to traditional single-motor drives. The fully enclosed structure, combined with atomizing nozzles and a negative-pressure dust collection system (such as the hood and dust collection box design in the patent), effectively controls dust dispersion and meets environmental protection requirements.

The double-deck linear dewatering and desliming screen demonstrates significant advantages in classification accuracy, processing capacity, energy conservation, and environmental protection through structural innovation, material upgrades, and intelligent control. It is particularly suitable for industrial scenarios with strict requirements on material particle size and large-scale processing. Its "multi-purpose" feature not only simplifies the process flow but also brings long-term economic benefits to users, making it one of the core pieces of equipment in modern mineral processing.

Structural Composition: It is mainly composed of a sieve box, vibrator, support system, and motor. The sieve frame is connected by high-strength bolts, and the sieve surface is composed of an arc section and a straight section. It can choose from strip slot sieve mesh, punched sieve plate, woven sieve mesh, or rubber sieve plate .

Working Principle: It adopts dual-motor self-synchronous technology. Two motors drive two independent vibrators to operate synchronously in opposite directions. The centrifugal force generated by the eccentric mass has components along the vibration direction, which are superimposed to form a single exciting force along the vibration direction, causing the sieve box to perform reciprocating linear motion.

Suitable for dehydration, dewatering, desintercalation and classification of washed products in coal preparation plant.

| No. | Screen Machine Model | Screen Hole Size (mm) | Screen Surface Structure | Feed Particle Size (mm) | Operating Frequency (Hz) | Single Amplitude (mm) | Processing Capacity (t/h) | Motor | Screen Machine Weight (Kg) | Fulcrum Operating Dynamic Load (±N) | Fulcrum Maximum Dynamic Load (±N) | |

| Upper Layer | Lower Layer | |||||||||||

| 1 | 2ZKB1848 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 20-360 | Y160L-6 | 8000 | 2250 | 9250 |

| 2 | 2ZKB1856 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 22-450 | Y160L-6 | 8700 | 2500 | 12500 |

| 3 | 2ZKB2065 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 22-500 | Y180L-6 | 12000 | 2880 | 14400 |

| 4 | 2ZKB2148 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 22-450 | Y180L-6 | 11500 | 3000 | 15000 |

| 5 | 2ZKB2160 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 22-520 | Y200L-8 | 12500 | 3600 | 18000 |

| 6 | 2ZKB2452 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 22-540 | Y225S-8 | 11750 | 4500 | 22500 |

| 7 | 2ZKB2460 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 25-540 | Y225S-8 | 13800 | 4000 | 20000 |

| 8 | 2ZKB3060 | 30-50 | 0.25-13 | Punching, Slotted | 0-300 | 16.2 | 3.5-5 | 25-600 | Y250M-8 | 16000 | 5000 | 25000 |

Shandong Xinjia Heavy Industry Technology Co., Ltd. specializes in coal washing equipment manufacturing with multiple national patents. Upholding quality as our foundation and integrity as our priority, we continuously strive for excellence to deliver high-performance screening systems that ensure reliable performance. Our commitment drives sustainable development across the global coal industry.