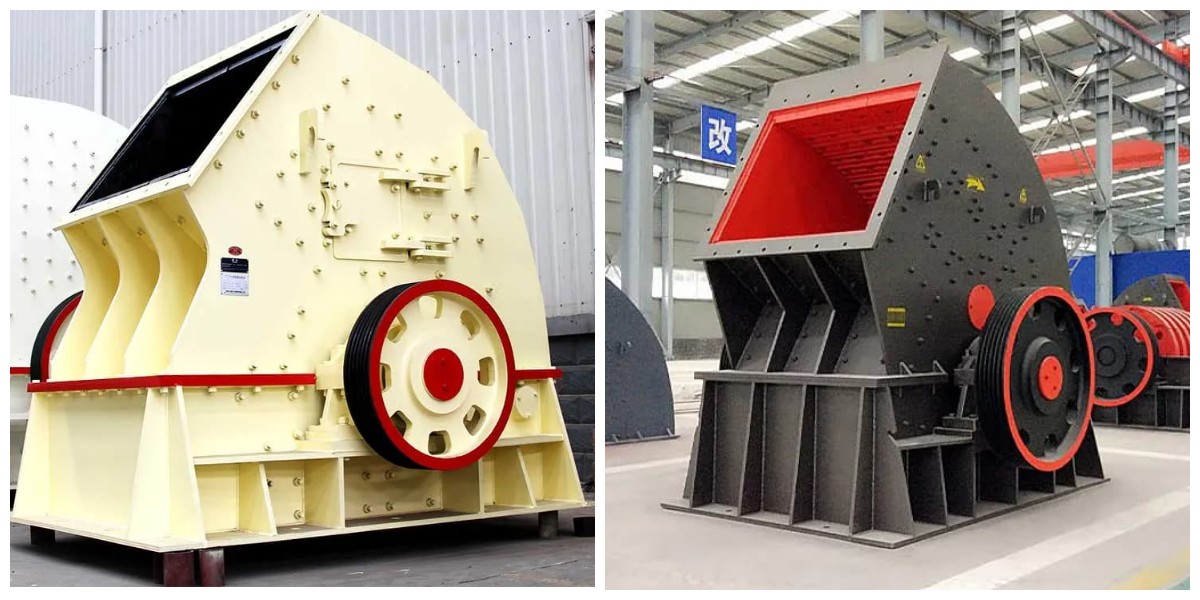

Hammer Mill Crusher

The structure is simple and compact, and the equipment operates smoothly.

It has a large crushing ratio and uniform product particle size.

The discharge particle size can be adjusted according to requirements.

It causes no dust pollution (for some sealed machine models).

It is wear-resistant and impact-resistant, with few wearing parts and convenient maintenance.

A hammer crusher is a crushing equipment that mainly works by impact, with additional shearing and grinding functions. It crushes materials by impacting them with high-speed rotating hammers, suitable for crushing medium-hard brittle materials with a compressive strength of ≤150MPa, such as limestone, coal, gypsum, salt, etc.

Hammer crushers mainly rely on impact energy to break materials. The motor drives the rotor to rotate at high speed, and materials enter from the upper feeding port. They are subjected to impact, shearing, and grinding by the high-speed moving hammers. Materials broken into sizes smaller than the screen hole pass through the screen plate for discharge, while those larger than the screen hole continue to be crushed until they meet the standard and are discharged.

It is mainly composed of the following components:

Rotor: The core component that drives the hammer head to rotate at high speed.

Hammer head: Directly strikes the material; it is a wear-prone part and needs to be replaced regularly.

Screen plate/Grate bar: Controls the discharge particle size and is adjustable.

Machine casing: Protects internal components; some models adopt a fully sealed design for dust prevention.

Main shaft, disc, and pin shaft: Support and connect the hammer head and rotor.

| Model | Rotor Specification (mm) | Max. Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Rotational Speed (r/min) | Electric Motor | Overall Dimension (mm) | Weight (t) | ||||

| Diameter | Length | Model | Power (kw) | Length | Width | Height | ||||||

| PC0606 | 600 | 500 | <200 | ≤50 | 20-40 | 1060 | Y225M-6 | 30 | 2228 | 1235 | 1005 | 1.95 |

| PC0808 | 800 | 700 | ≤200 | ≤50 | 30-65 | 1060 | Y280S-6 | 45 | 2418 | 1550 | 1282 | 2.65 |

| PC1010 | 1000 | 1000 | ≤200 | ≤50 | 65-120 | 1060 | Y315M-6 | 90 | 2800 | 1838 | 1897 | 5.04 |

Shandong Xinjia Heavy Industry Technology Co., Ltd., a leading industry pioneer, specializes in precision manufacturing of coal washing and mining equipment. Since its establishment, the company has achieved rapid growth, demonstrating formidable capabilities and potential. With multiple invention patents and robust technical expertise, its flotation equipment automatically adjusts to flotation conditions, ensuring optimal performance. The coal washing systems it produces effectively resolve coal feeding blockage issues while enhancing operational efficiency.