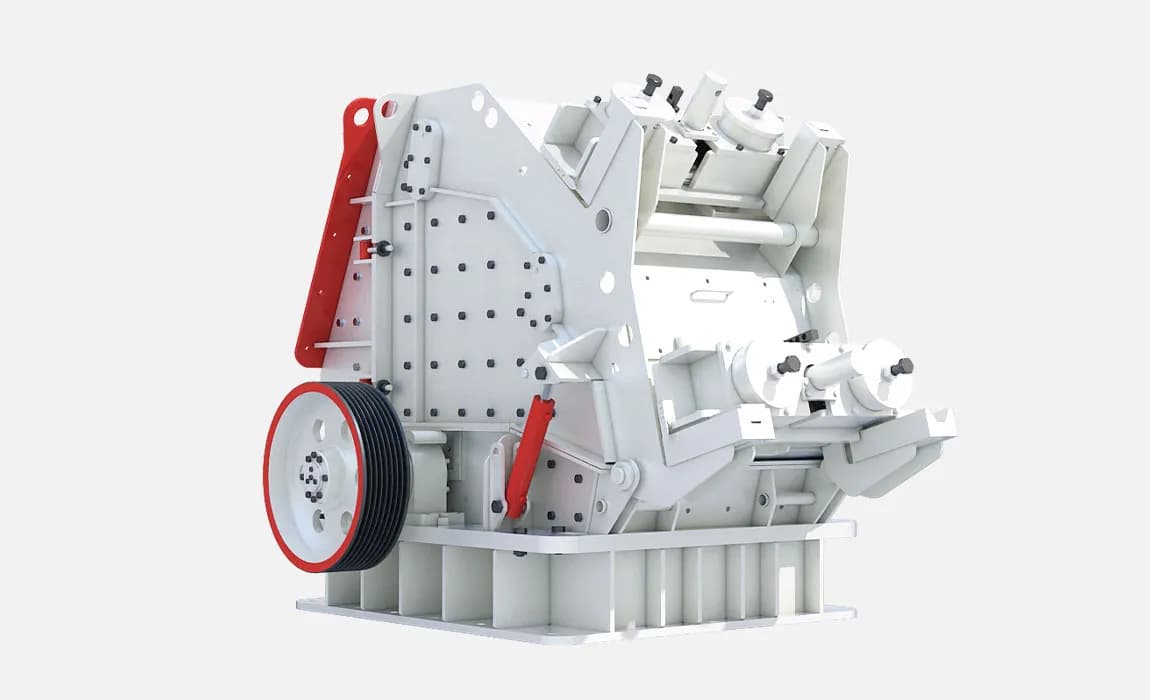

Impact Crusher

Low energy consumption and high crushing efficiency.

Wearable parts such as hammer plates and liners have a long service life, resulting in low operating costs.

The discharge particle size is adjustable to meet different process requirements.

It can be used in combination with jaw crushers to form an efficient crushing process.

The equipment has a compact structure, making maintenance and inspection convenient.

Impact Crusher, also known as, is a high-efficiency equipment that crushes materials by utilizing impact energy. It is widely used in fields such as building materials, metallurgy, chemical industry, hydropower, mining, and expressways. It can process medium-hard materials with a side length of 100-500 millimeters and a compressive strength not exceeding 350 megapascals, such as limestone, granite, concrete, and iron ore. It has the advantages of a large crushing ratio, high production efficiency, good product particle shape, and simple maintenance.

After the material enters the crushing chamber, it is impacted by the high-speed rotating hammer and thrown against the反击板 (rebound plate) for secondary crushing. Then, it is repeatedly crushed between the hammer and the until its particle size is smaller than the set value, after which it is discharged. Adjusting the gap between the反击板 and the rotor can control the discharge particle size and shape.

Impact crushers are suitable for coarse, medium, and fine crushing of various medium-hard materials, especially in fields such as highways, railways, hydropower stations, and construction waste treatment. Their product particle size is uniform and the shape is good, making them commonly used equipment in modern sand and gravel aggregate production lines, cement plants, concrete mixing stations, and other industries.

Main Features

High reduction ratio, up to over 50, suitable for single-stage crushing.

Excellent product particle shape, low needle and flake content, more cubic particles, which can meet the high-standard requirements of engineering projects such as high-grade highways and railways.

Compact structure, convenient maintenance, multi-chamber crushing design, quick inspection and repair.

Low energy consumption, high output, simplified crushing process, low operating cost.

Wide application range, dry and wet crushing, and has no strict requirements on the moisture content of materials.

| Model | Specification (mm) | Feeding Port Size (mm) | Max. Feeding Size (mm) | Production Capacity (t/h) | Motor Model | Motor Power (kw) | Weight (t) | Overall Dimension (L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 35-50 | Y250M-6 | 37 | 9.5 | 1800×1600×1800 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | Y315S-6 | 75 | 14 | 2340×2007×2500 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-120 | Y315L1-6 | 110 | 17 | 2582×2053×2809 |

| PF-1212 | Φ1250×1200 | 400×1250 | 350 | 70-140 | Y315L2-6 | 132 | 17.5 | 2582×2203×2809 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | Y315L2-6 | 132 | 22 | 2582×2403×2809 |

| PF-1315 | Φ1300×1500 | 860×1520 | 500 | 90-220 | Y2-335M2-6 | 200 | 26 | 2930×2761×3053 |

Shandong Xinjia Heavy Industry Technology Co., Ltd. crafts exceptional products through masterful craftsmanship and rigorous quality standards. Driven by innovation, we continuously develop cutting-edge technologies and innovative solutions to meet diverse industry needs. Our efficient and reliable equipment empowers clients to boost operational efficiency. From production systems to comprehensive solutions, we demonstrate professional expertise and technical prowess. By partnering with Xinjia Heavy Industry, you'll gain a powerful competitive edge to stand out in the market and co-create a brilliant future together.