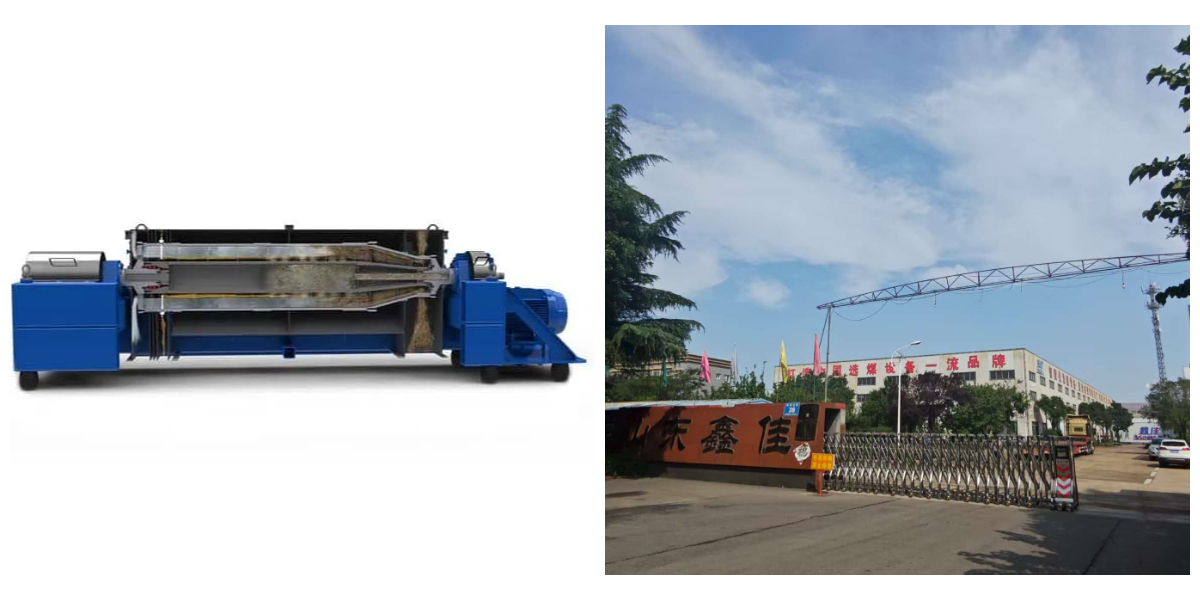

Horizontal Dehydrator

High efficiency and energy saving: Large processing capacity, low energy consumption, electricity consumption per ton of coal is reduced by 15% to 20% compared with traditional equipment.

Convenient maintenance: Few vulnerable parts (mainly screen baskets), horizontal maintenance, small space occupation.

High degree of automation: Supports linkage with medicine preparation machines, sludge feed pumps, etc., to achieve 24-hour unmanned operation. Strong adaptability It is suitable for materials with high humidity and high viscosity, such as coal slime, tailings, sludge, etc.

Horizontal vibrating centrifugal dewatering machine is a solid-liquid separation equipment widely used in industries such as coal, ore, chemical engineering and environmental protection. It mainly separates water from materials through the centrifugal force generated by high-speed rotation to achieve efficient dewatering. The core working principle is as follows: Materials enter the bottom of the screen basket through the feeding pipe. Under the action of centrifugal force and vibration, moisture is discharged through the screen holes, while solid materials move along the screen surface to the discharge port, completing the dehydration process.

The equipment adopts a dual-motor synchronous excitation system to precisely control the axial amplitude of the screen basket from 2 to 6mm. Combined with forced lubrication and wear-resistant ceramic lining design, it significantly enhances operational stability and service life.

Key technologies include: Dual-body vibration technology: smooth operation, low noise, vibration motor temperature ≤85° C.

Intelligent detection interface: Supports Internet of Things connection, and needs to pass a 4-hour no-load test before leaving the factory.

Wear-resistant protection: Key parts such as the screen basket, feeding pipe, and discharge cavity are made of wear-resistant stainless steel or ceramic lining.

Decentralized lubrication system: Reduces maintenance frequency and lowers maintenance costs.

| Parameter | Unit | Model | ||||

| TWZ850 | TWZ850 | TWZ850 | TWZ850 | |||

| Feed Particle Size | mm | 0.5~50 | 0~50 | ≤50 | 0.5~50 | |

| Processing Capacity | t/h | 100~150 | 180~250 | 200~300 | 250~350 | |

| Product Moisture | % | 5~9 | ||||

| Screen Bowl Large End Diameter | mm | 1150 | 1300 | 1400 | 1500 | |

| Screen Slot Size | mm | 0.25, 0.3, 0.35, 0.5 | ||||

| Screen Bowl Vibration Frequency | Hz | 25 | 25 | 25 | 25 | |

| Double Amplitude | mm | 4~6 | ||||

| Main Motor Power | Kw | 37.5 | 45 | 55 | 75 | |

| Vibration Motor Power | Kw | 7.5 | 7.5 | 11 | 15 | |

| Oil Pump Motor Power | Kw | 0.55 | 0.55 | 0.55 | 0.55 | |

| Overall Dimension | Length | mm | 2800 | 2700 | 3100 | 3170 |

| Width | mm | 1930 | 2260 | 3090 | 2975 | |

| Height | mm | 1930 | 2245 | 2295 | 2400 | |

| Equipment Weight | Kg | 5527 | 6500 | 9200 | 10000 | |

Note: The external moisture content of the product is related to the properties of the material, particle size composition, and processing capacity, but mainly depends on the content of coal sludge in the feed. When the content of-0.5mm particle size in the feed is less than 10%, the external moisture content of the product is generally 5~9%.

Shandong Xinjia Heavy Industry Technology Co., Ltd., a leading enterprise in the industry, specializes in the meticulous manufacturing of coal washing and coal mining equipment. Since its establishment, the company has achieved rapid growth, demonstrating strong capabilities and potential.