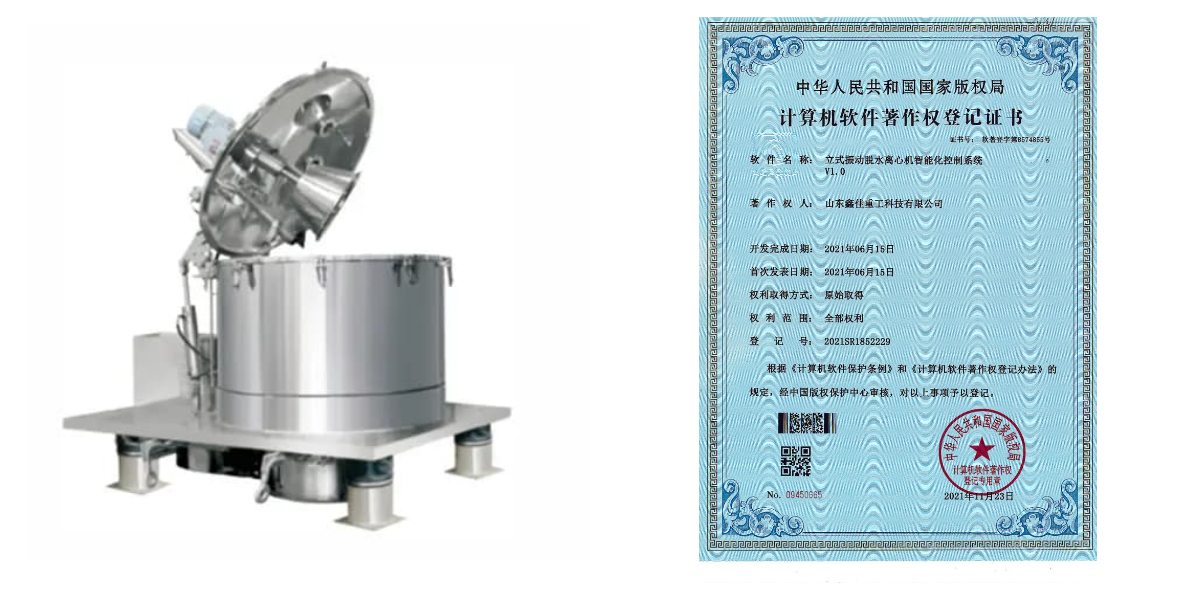

Dewatering Machine

It features high separation efficiency, low product moisture content, high degree of automation, stable operation, and convenient maintenance, meeting special process requirements such as high cleanliness, explosion-proof, and airtightness.

The vertical scraper discharge centrifugal dewatering machine is a highly efficient solid-liquid separation device, widely used in the chemical, food, pharmaceutical, environmental protection and other industries. The main principle is that the motor drives the drum to rotate at high speed. After the material enters the drum evenly from the top, under the action of centrifugal force, the liquid phase passes through the filter screen and is discharged, while the solid phase is retained in the drum to form a filter cake. Then, it is automatically scraped off by the scraper device and discharged from the lower discharge port.

Product structure features: Fully enclosed design: Meets the requirements of airtightness, explosion-proof and GMP certification, suitable for handling flammable, explosive, toxic or high-cleanliness materials

Automation control: PLC or touch screen program control is adopted, and variable frequency drive is used to achieve smooth start and stop as well as energy-saving operation. The entire process (feeding, separation, washing, dehydration, and unloading) is automated and can be remotely monitored

Hygiene and Safety: Equipped with online cleaning (CIP) systems, gas-assisted scrapers, nitrogen protection and other devices, it reduces manual intervention and enhances operational safety and cleanliness

Vibration isolation installation: Liquid damping vibration isolators or elastic damping structures are adopted. There is no need to pour a foundation. It can be directly placed on the ground or floor slab, with low vibration and noise

High efficiency and energy saving: The energy consumption braking technology can feed the braking energy back to the power grid, improving energy efficiency by 18% to 24%, while optimizing the fabric and washing systems and reducing the amount of washing water used

| Parameter/Specification | Feed Particle Size (mm) | Feed Moisture (%) | Processing Capacity (t/h) | Product External Moisture (%) | Screen Gap (mm) | Main Motor Power (KW) | Lubrication Motor Power (KW) | Overall Dimensions (mm) | Machine Weight (KG) |

| TLL700A | 13-0 | ≤30 | 50 | 5-8 | 0.5 | 15 | 0.75 | 2175x1690x1955 | 3125 |

| TLL900A | 25-0 | ≤30 | 100 | 5-8 | 0.5 | 45 | 0.75 | 2765x2030x2350 | 5240 |

| TLL1000A | 25-0 | ≤30 | 150 | 5-8 | 0.5 | 55 | 1.1 | 3010x2250x2515 | 6465 |

| TLL1150A | 25-0 | ≤30 | 200 | 5-8 | 0.5 | 75 | 1.1 | 3265x2460x2705 | 9200 |

In the field of energy equipment manufacturing, Shandong Xinjia Heavy Industry Technology Co., Ltd. has always taken technological innovation as the core driving force, focusing on the research and development, production and sales of coal washing equipment and coal mine equipment, and has become a benchmark enterprise in the industry with its core strength. Leveraging multiple proprietary invention patents, the company has overcome traditional equipment limitations. Its intelligent coal washing system enables real-time precision control of washing parameters, significantly enhancing coal processing efficiency and quality. The specially designed coal mine conveyor equipment, optimized through structural engineering, effectively reduces equipment failure rates and lowers maintenance costs for mining enterprises. Behind every product lies Xinjia Heavy Industry's relentless pursuit of technical excellence.