ore concentrator

High efficiency and energy saving:By adopting flocculation technology and inclined plate design, the sedimentation speed is increased by 4 to 8 times, and the processing capacity is large.

High degree of automation: Equipped with hydraulic automatic rake lifting, PLC control, and pressure sensing protection, it realizes intelligent operation.

Compact structure: The central drive design saves space and is suitable for medium and small-sized pools (with diameters ranging from 3 to 35 meters).

Easy maintenance: Modular design, supporting automatic cleaning and remote diagnosis.

Strong adaptability: It can be used for sludge concentration with a solid content as low as 1%, and the output concentration can reach over 3%, which is convenient for subsequent dewatering.

The central drive rake type thickener is a highly efficient solid-liquid separation equipment based on the principle of gravity sedimentation. It is mainly used for the dewatering treatment of concentrates and tailings in mineral processing plants and can also be widely applied in industries such as coal, metallurgy, chemical engineering and environmental protection. This equipment drives the rake frame to rotate through the central transmission system, scraping and collecting the sludge that has settled at the bottom to the central discharge port of the pool for discharge. Meanwhile, the clear water overflows from the weir at the upper part of the pool, achieving continuous concentration and clarification.

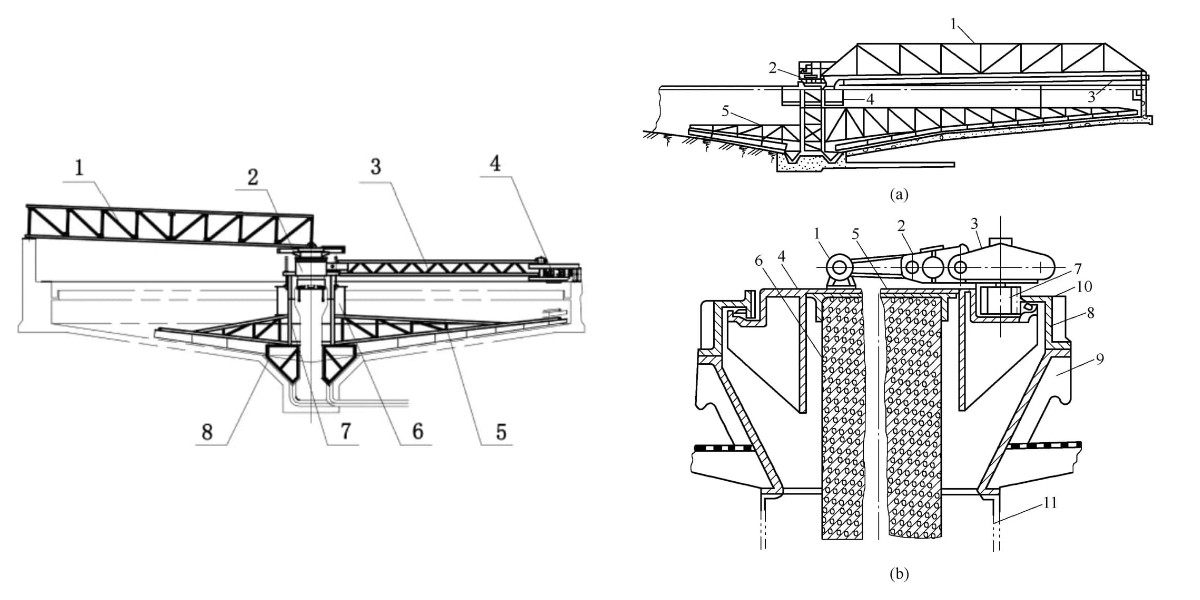

The central drive rake type thickener is mainly composed of the following components:

Thickening tank: Circular structure, with a gently conical or horizontal bottom, used for slurry sedimentation.

The rake frame and the sludge scraper: symmetrically arranged, the scrapers are in an oblique shape, continuously collecting sludge. Some models are equipped with bars to enhance the concentration effect.

Transmission device: including motor, reducer, central main shaft, etc., drives the rake frame to rotate at a low speed (usually 0.3-1.2 revolutions per minute).

Lifting device: Equipped with manual or automatic rake lifting function. When overloaded, the rake frame can be raised to protect the equipment.

Dosing system (for some models) : Supports the addition of flocculants to enhance sedimentation speed and treatment efficiency.

Electronic control system: Supports local/remote control, and some are equipped with PLC automatic monitoring and fault alarm functions.

| Model | Diameter of Concentrator Tank (m) | Depth of Concentrator Tank (m) | Settling Area (㎡) | Rotation Time per Revolution of Rake Frame (min/r) | Rake Lifting Height (m) | Processing Capacity (t/d) | Driving Power (kw) + Rake Lifting Power (kw) |

| NZX-15 | 15 | 4-5 | 176 | 5-10 | 400 | 350-500 | 5.5+3 |

| NZX-18 | 18 | 4-5 | 254 | 8-12 | 400 | 500-800 | 5.5+3 |

| NZX-20 | 20 | 4-5 | 314 | 8-12 | 500 | 800-1000 | 5.5+3 |

| NZX-24 | 24 | 5-6 | 452 | 8-12 | 500 | 1000-1300 | 7.5+3 |

| NZX-30 | 30 | 5-6 | 706 | 10-15 | 500 | 1300-1600 | 7.5+4 |

| NZX-32 | 32 | 6-8 | 803 | 15-20 | 500 | 1500-1800 | 11+4 |

| NZX-35 | 35 | 6-8 | 961 | 15-20 | 600 | 1600-2000 | 11+4 |

| NZX-40 | 40 | 6-8 | 1256 | 15-20 | 600 | 2000-2400 | 15+4 |

| NZX-45 | 45 | 6-8 | 1589 | 18-22 | 600 | 2400-2800 | 15+4 |

| NZX-50 | 50 | 6-8 | 1962 | 18-22 | 600 | 2800-3200 | 18.5+4 |

The company recognizes technological innovation as the lifeblood of enterprise development. With a professional technical team, it has accumulated multiple invention patents and deeply integrated advanced technologies into its products. Its high-efficiency flotation machines feature unique stirring and aeration structures that enable efficient separation of coal and impurities, significantly improving flotation recovery rates. The coal washing wastewater treatment equipment facilitates water recycling, helping coal mining enterprises implement green production concepts.